Elements are driven into the soil by generating vibrations in the adjacent soil particles in order to reduce the natural resistance. Depending on the technology used, these vibrations may vary from a limited spread to a perimeter of kilometers!

The dynamic weight of a hydraulic hammer or pile driver produces a high pulsating load at a low frequency. With a vibratory hammer, the opposite will occur: a relatively low steady load at a high frequency. Thanks to the low impact of the vibratory hammer, the risk of fractures and cracks is eliminated.

A vibratory hammer is used to drive sheet piles, pipes or other elements into the soil by vertical vibrations. The adjacent soil particles are put into motion and thus the soil is ‘loosened’. The dynamic weight of the hammer will drive the elements into the soil (extracting is done with a crane).

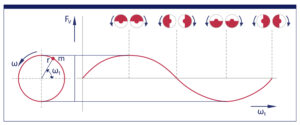

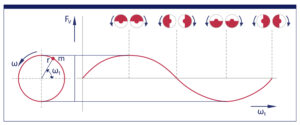

Fv = vartical force

w = angular frequency

wt = agular frequency π–radian

m = mass

r = rotations per minute

The weights are driven by hydraulic engines. The eccentrics are gear connected to maintain proper synchronisation. The eccentric shafts are mounted in heavy-duty roller bearings. The maximum capacity of the engines is hydraulically limited.

Suppressor housing

The extraction head contains rubber elements (elastomers) to isolate vibrations from the vibration case to the crane or pile driving rig. The tare weight of the suppressor housing advances the driving speed.

Hydraulic clamps

As an option, the hydraulic clamp contains two gripping jaws, one fixed and one moveable. A cylinder, integrated in the clamp body, operates the moveable jaw and has a pilot operating check valve that keeps the cylinder under pressure in case of hose damage. The clamp is operated hydraulically.