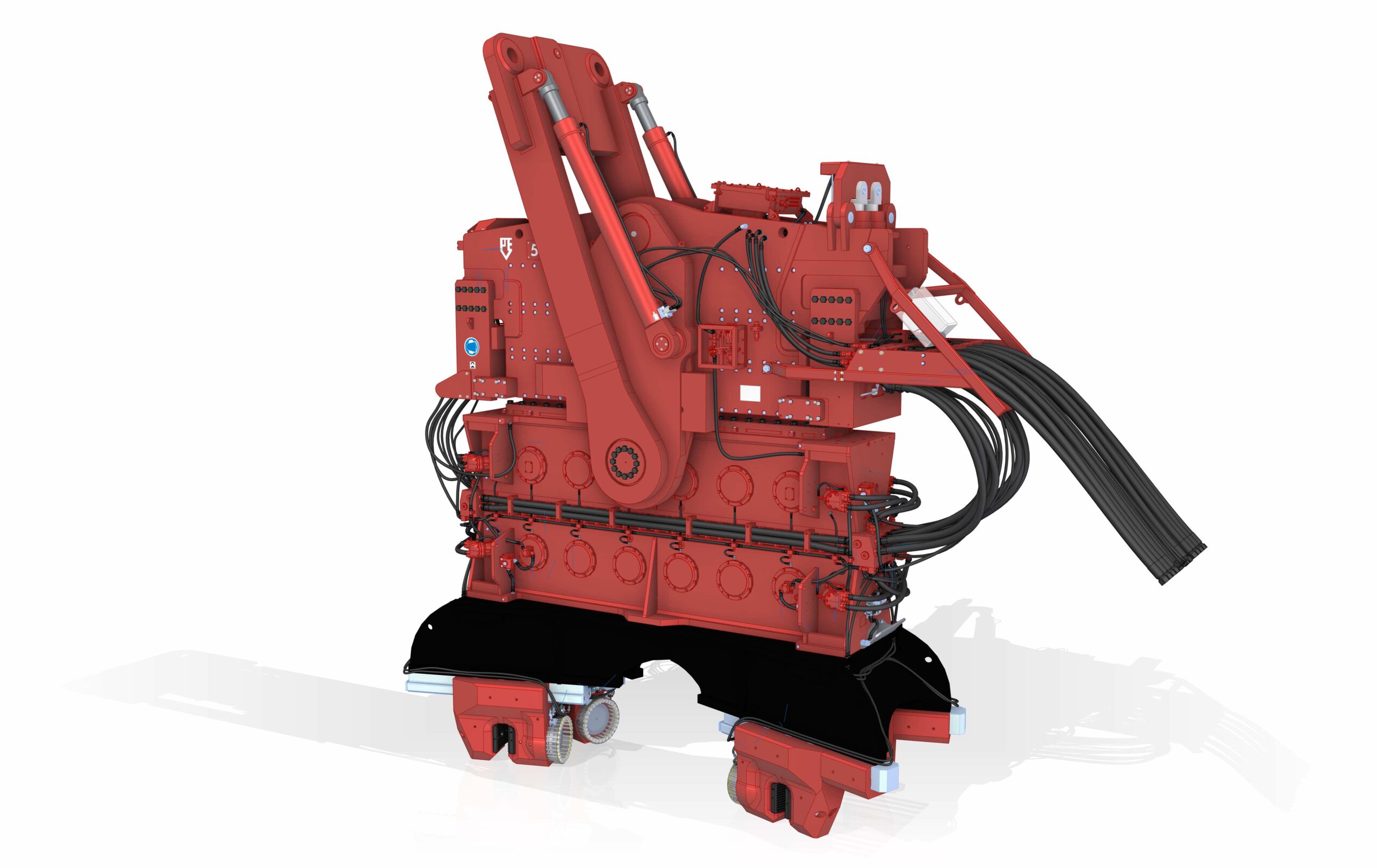

Recently, Dieseko’s newest offshore Upending Vibratory Hammer passed the FAT-test and is now DNV-certified for offshore lifting appliances. This machine was developed for the efficient and safe installation of Anchor Piles and Pin Piles in the renewable energy market.

- World's biggest Upending Mono Vibratory Hammer

- DNV Certified for offshore Lifting appliances

- Newly designed tilting bracket for extra lifting capacity

0 kgm

Eccentric moment

0 ton

Total weight

0 ton

Maximum lifting weight

Main features of the 500MU

- Suitable for heavy duty (offshore) pile installation

- High quality product

- Forced lubrication cooling system

- Highly efficient

- Huge time savings, thus cost savings

- Makes your machine suitable for multiple applications

- Saves additional tilting equipment

- Reducing deck space on the vessel

This biggest mono vibratory hammer in the world weighs 108,000 kg and has a lifting capacity of another 301,000 kilograms. The Vibro hammer has 500kgm of eccentric moment and is driven by two power units that supply 3,200 litres of hydraulic oil under a pressure of 320 bar. This 500MU is a 12-eccentric vibratory hammer. A separate electric-hydraulic power pack powers the Upend system. The upend system allows the machine to tilt and pick up a horizontal stored tube. This saves a lot of time and makes additional auxiliary installations unnecessary. But the real gain is for the sea life because vibro installation is the least harmful technique.

PVE 500MU

This unique Upending Vibratory Hammer is part of our rental fleet. The 500MU provides a real USP when deck space is limited.

Specifications

Development

Over the past two years Dieseko engineers have focused on the engineering of this new machine. It is the largest vibratory hammer ever built! The engineering challenges led to important innovations including a newly designed tilting bracket, increased lifting capacity, as well as a hydraulic safety lock that is activated during the pile upending procedure.

Power & Emission

Low-emission and zero-emission are key. This important aspect is also part of Dieseko’s strategy. Two coupled PVE 1600, Stage-V, Power Packs provide the required 3,200L oil flow. Controlling the clamps and the upending and locking system is done with a 100% emission-free electric-hydraulic power unit.

Our team has great drive and enthusiasm to support and accelerate the energy transition by innovative foundation solutions. This new 500MU development is a great example of that.”

Dirk Smulders – CEO

Based on the 300MU, The first upending vibro hammer ever

The PVE 500MU is a further development of the patented PVE 300MU Upending Vibratory Hammer. Dieseko’s Upending concept was first introduced in 2012 at the Global Tech I wind farm in Germany.

300MU in Hochtief Global Tech I project

In this project 240 PIN piles, up to 60 meters in length were picked up, positioned and vibrated directly for the first time in history, without an auxiliary crane. With this efficient way of installation, Dieseko opened the eyes of the world to the use of Vibratory Hammers in offshore applications.

We test, test and test until everything is 100% secured to perform perfectly.”

Pierre Bouchet – Mechanical Engineer

Want our expertise? Connect with us!

Rob Eijkens

Technical Manager Offshore

Jos Hardeman

Senior Sales Area Manager - Mid-Europe, Scandinavia, UK

Mayor de Vries unveils new PVE 500MU

PVE 500MU passed the DNV offshore classification test