For soil layers with insufficient bearing capacity with a high risk of settlements, ground improvement is a must. For this reason, Dieseko Group offers a wide range of equipment for different methods. We offer equipment for compaction methods for soil layers, mainly sand, with relative loose density. For soil layers with poor permeability, Dieseko Group provides equipment to install vertical drains. Incompressible soil layers with insufficient bearing capacity, soil replacement equipment for stone, grout, concrete, gravel, sand or chalk is available.

Vibroflot deep vibration compaction

Soil particles are rearranged and compacted by introducing vibrations into the soil. The vibrating and oscillating movement of the Vibroflot is generated by the hydraulic-powered eccentric weight. At full water pressure the oscillating vibrator penetrates to the design depth and is surged up and down to agitate the soil. At full depth, the water flow is reduced or stopped. The volume reduction of the soil can reach compaction values up to 15%

Replacement

Vibro Replacement is a method of constructing densely compacted stone columns, using a depth vibrator to densify the aggregate backfill and surrounding granular soil. The technology is used to treat clays, silts and mixed stratified soils and improve their load bearing, settlement characteristics, and to reduce seismic subsidence, reduce lateral spreading and liquefaction potential.

• Vibroflot Bottom Feed

With the bottom feed method, the stone particles are fed to the tip of the Vibroflot through a material transfer pipe which is fastened to the side of the Vibroflot.

• Vibroflot Top Feed

This method can be applied for the densification and reinforcement of granular soils. While compacting the soil with a Vibroflot a wheel loader moves granular material around the Vibroflot shaft at work level. The granular material is disposed of along the Vibroflot shaft supported by water jetting at the same time.

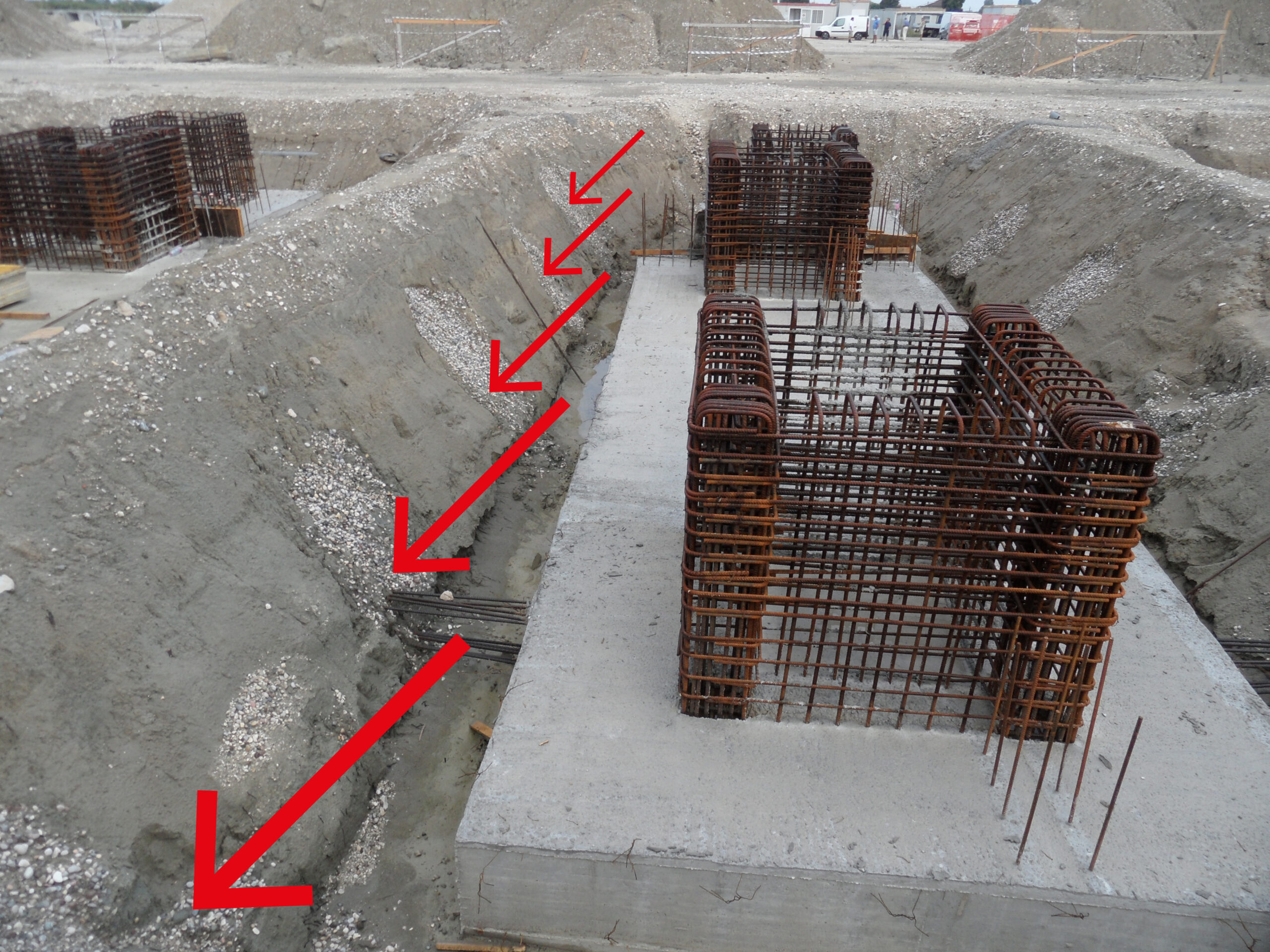

Stone Columns

Stone columns refer to columns of compacted gravel size stone particles to improve the performance of soft or loose soils. The method is used to increase bearing capacity, reduce foundation settlement, improve slope stability, reduce seismic subsidence, reduce lateral spreading and liquefaction potential, permit construction on loose soft fills.

Grout Columns

In general grout columns are constructed by driving, drilling or vibrating a temporary thick-walled casing with lost tip or valve into soft soils. After the required depth has been reached, the casing is filled with grout, a mixture of water and cement, and withdrawn. After the casing has been extracted a grout column is made in situ. These are executed in a certain grid providing the complete soil massive with higher stiffness and bearing capacity. Grout columns are easy and economic to perform and by choosing the installation method such as vibrating, drilling or driving the method can be used in almost any environment.

Dieseko Group Ground improvement equipment:

Applications

Compaction, drainage, replacement, stone columns, grout columns

The Dutch are experts in solving and overcoming maritime and civil challenges due to the centuries of struggle and battle to keep the Lowlands we live on protected and dry to the ever rising sea level.”

For more information:

Jos Hardeman

Senior Sales Area Manager - Mid-Europe, Scandinavia, UK

Marion van den Akker

Area Manager BeNeLux