Introduction to offshore foundations: a Dieseko Group strategic pillar.

It is precisely at the project level where we are in constant dialogue with large contractors to jointly develop tailor-made solutions for the challenge of delivering reliably, safely and on time. The vibratory-driving method represents a suitable alternative installation technique. The execution reveals clear advantages comparing to the conventional impact hammering. Both, the noise emission and the installation time can be decreased.

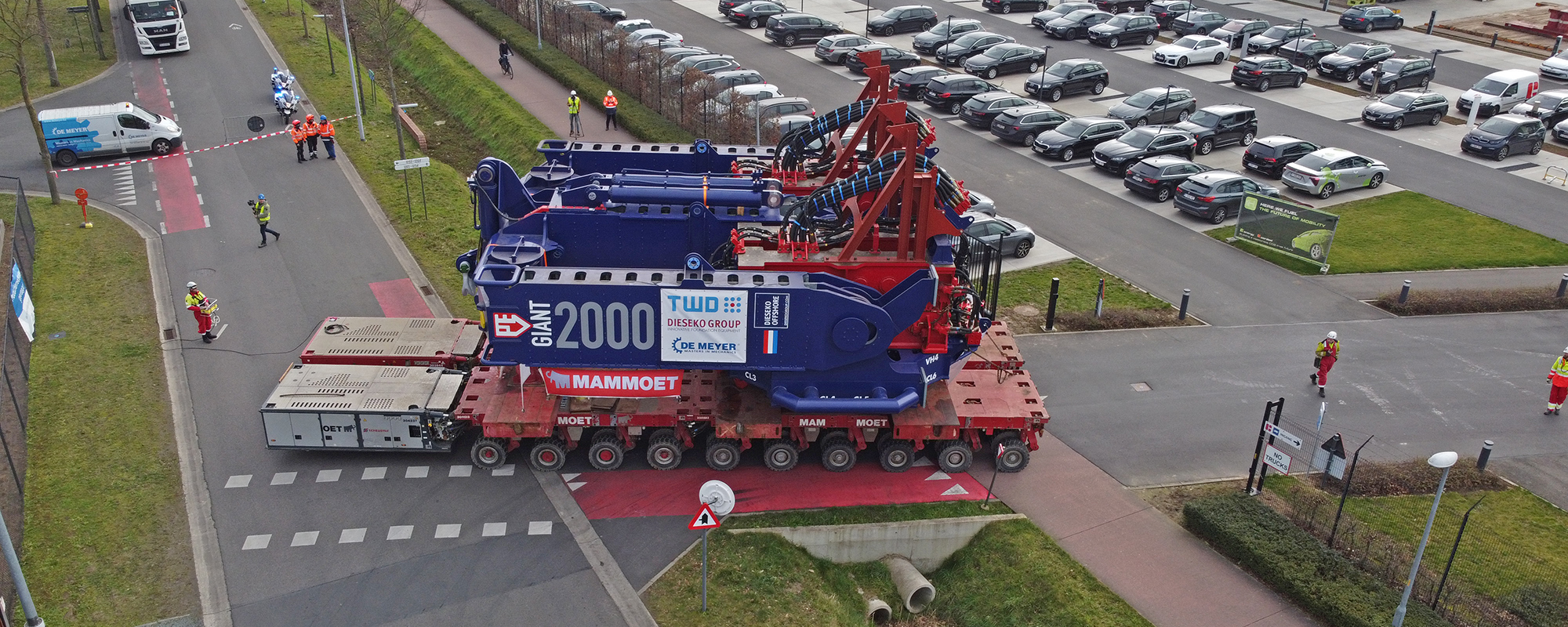

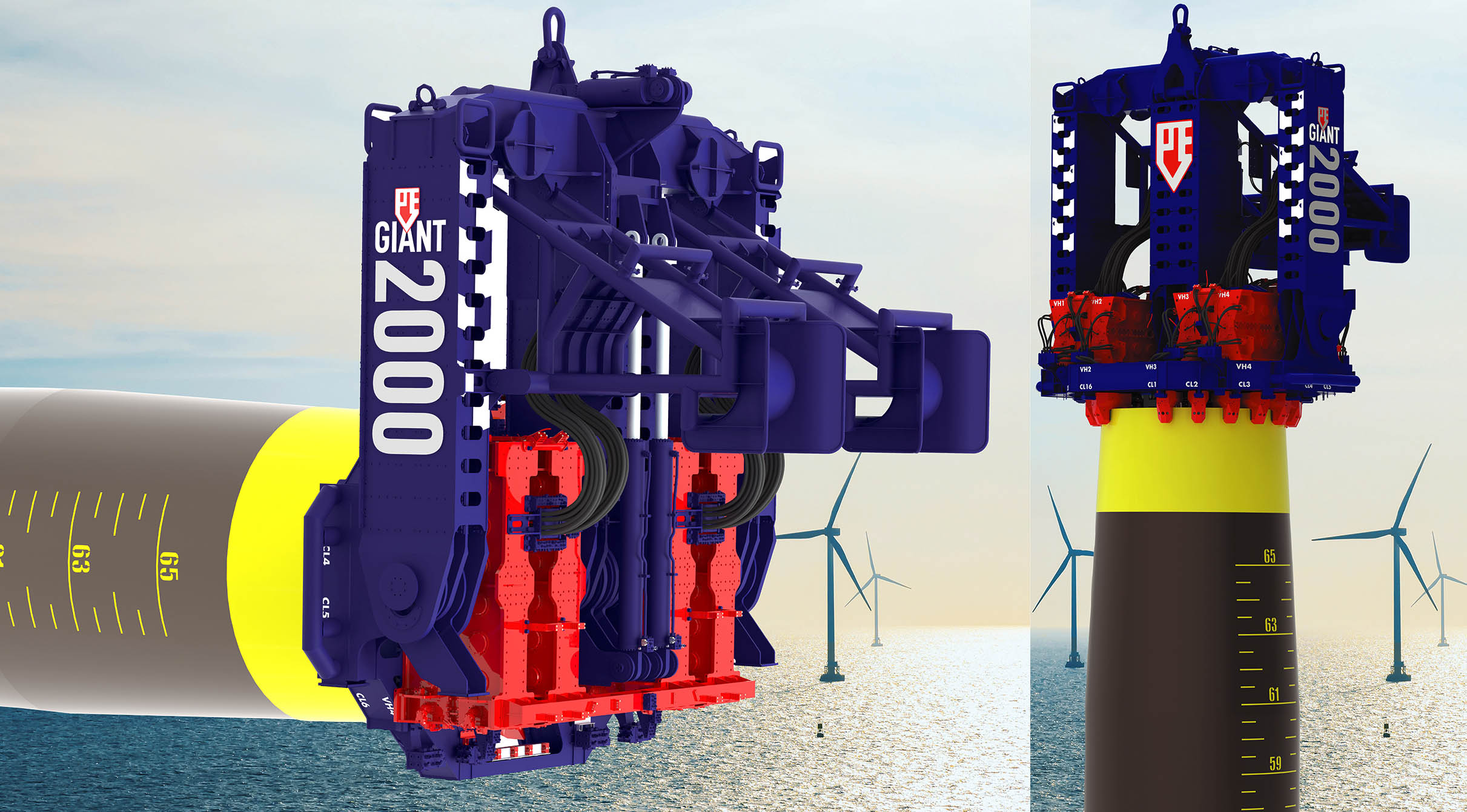

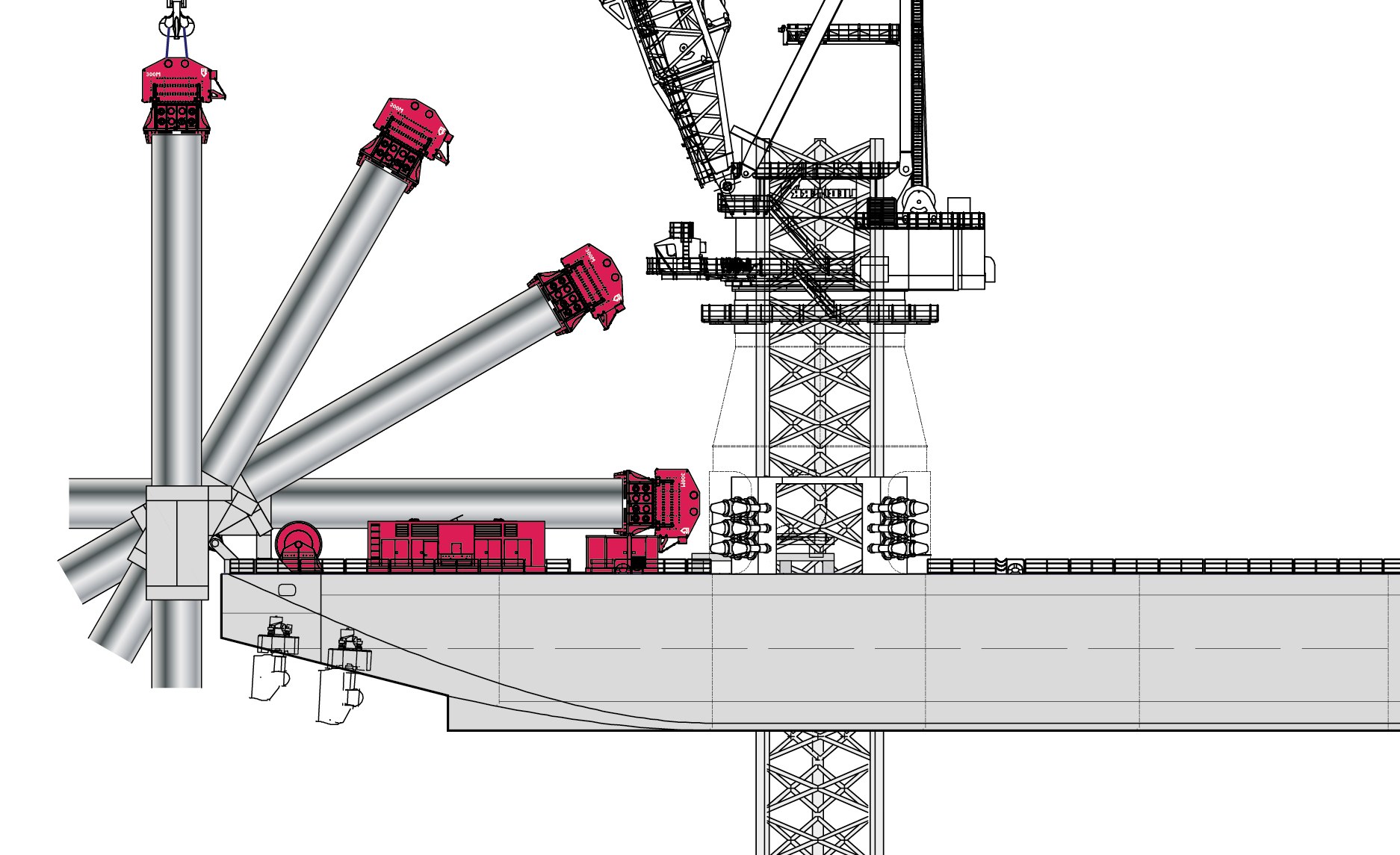

Added: We strive to work with our clients at project level, so that our engineers can work on a tailor-made solutions that meet the project requirements and that are delivered on time. A good example of this type of cooperative client-supplier relationship is the GIANT that was developed and built for Saipem. It offers 2000kgm of power! Our commitment was: safety first, eliminate risk, innovate yet offer a reliable solutions.

Certification & Staff

Our products, organization, and our trained offshore operators are all correctly certified.

Special features on our equipment, such as the up-ending mechanism, as well as the load bearing parts, were designed, tested and certified in accordance with DNV Lifting Appliances. The GIANT 2ooo has been certified to work with casings with a top diameter of 8000mm and a weight of 1600t.

Vibro Technology

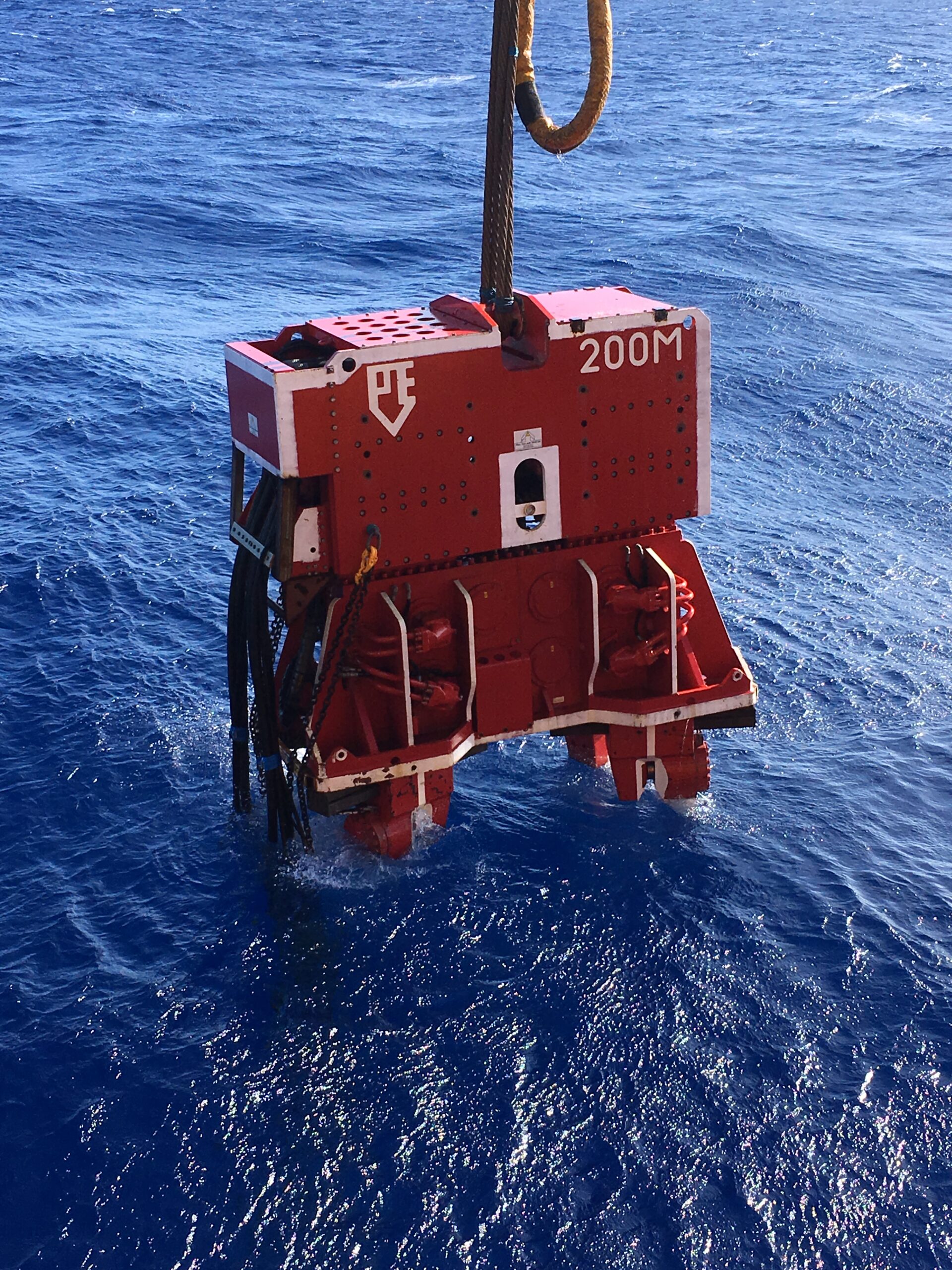

A vibratory hammers is made up of a vibrating gear case connected by elastomers to the suppressor head. The top part of the hammer does not vibrate and can be safely hoisted by a crane.The vibratory hammer is a mechanical sine-wave oscillator with weights rotating eccentrically in opposite directions. The effect of the vibrations is an oscillating vertical force classified to frequency and amplitude. Vibratory hammers work by eliminating soil resistance acting on the pile.

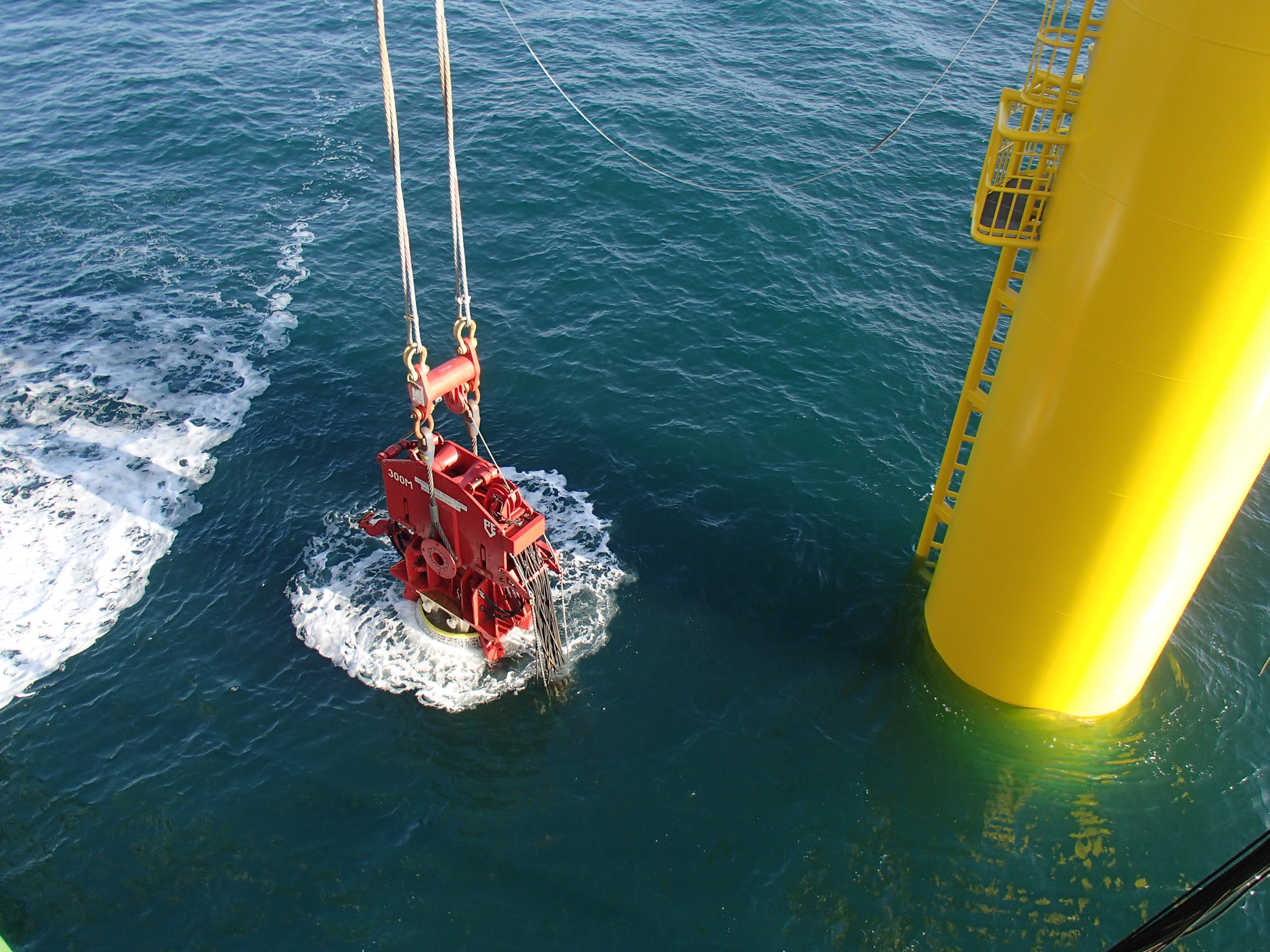

Vibration technology is a very attractive option for offshore applications. A vibratory hammer’s handling and driving speed are great, up to 10 times faster than working with an impact hammer. Dieseko Group has built up an extensive track record offshore by installing Monopiles, Anchor piles and Pin piles. Dieseko Group has 45 years of experience with this technology and supported by our innovative approach, we have already come up with many smart solutions, such as upending, where the vibratory hammer can tilt to pick up a horizontal pile and put it upright for installation.

Watch our 2021 offshore video here.

Upending and driving in one sequence

Due to tilting, the vibratory hammer can clamp onto a horizontally stored pile to lift and drive the pile vertically without any other handling operations.

- Highly efficient

- Substantial time savings = cost savings

- Transforms the Vibro into a multifunctional foundation machine

- This method can be applied both onshore and offshore

Bearing capacity and stability

On land, forces on foundation piles are mainly axially. Vibration technology has been a commonly used installation method there for decades. In the offshore wind sector, monopiles are loaded both axially and radially. Typically, vibration installation results in a slight reduction in radial load capacity. Hammering the pile to design depth for the last bit is a usual solution.

Environmental impact by vibration: emissions

The noise nuisance during pile driving at sea has an enormous environmental impact. The potential damage to marine life is evident. The German authorities have set a threshold value for these emissions of SEL 160 dB re 1µPa2 and SPLpeak peak 190 dB re 1µPa2 at a distance of 750 m from the source. The industry is rapidly developing models to assess project noise emissions based on power, pile geometry, and soil response.

During dismantling four offshore wind turbine foundations, acoustic measurements s were performed with a Dieseko PVE 500MU vibratory hammer. The measured sound levels were significantly below the thresholds set by the German authorities. More information is available on request.

An overview of our track record in offshore

PVE GIANT 2000 Upending Vibro

PVE 500MU Upending Vibro