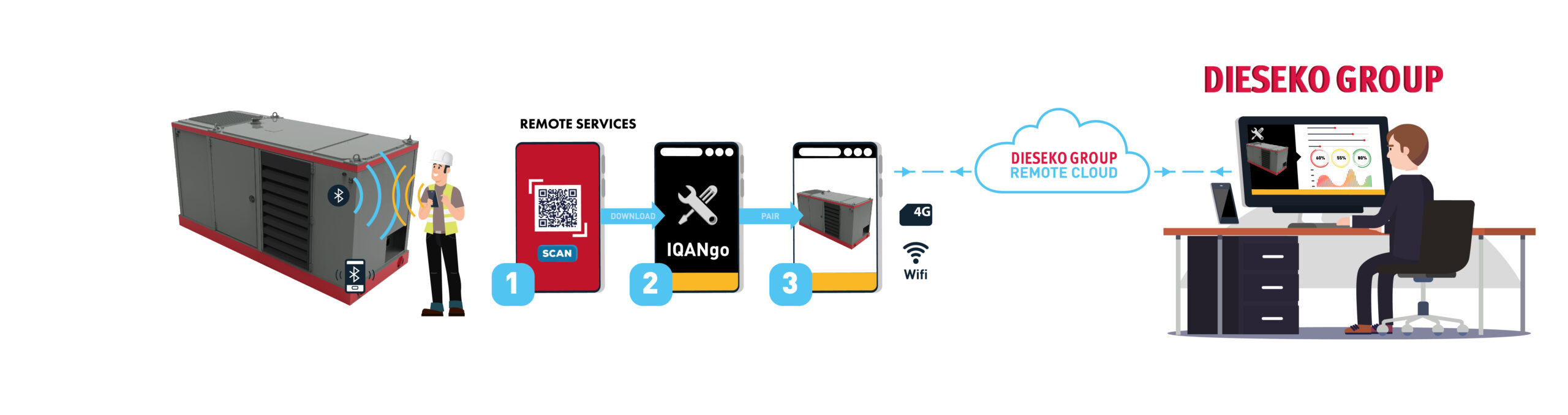

Dieseko Group offers a data logging and condition monitoring system (DriveLink) for Power Packs and Side Grippers. This feature is available for new equipment and as an aftermarket version in all MD4 equipped Power Packs. All new Power Packs and Side Grippers are equipped with the required Drivelink Dongle and software update. This easy to install system provides remote services to assist with remote assistance.

The aftermarket version can easily installed on location or when the Power Packs is brought to Dieseko Group for maintenance. The installation of the hardware can be done by your own mechanics. Installation time is about 1 hour.