The construction market demands solutions to control noise emissions in the city and on the construction site. Noise no longer has to be an issue during sheet pile installation. Dieseko has focused on the two sources of sounds emissions and has development of noise-reducing solutions for both.

Mastering piling noise

Introduction to Dieseko Group’s noise reduction solutions

Acoustic Louvres for Power Pack

The first sound source is the Power Pack, for which specially prepared acoustic louvres have been developed that can dampen the noise by up to -9 dB. The sound is muted by smart geometry and rock wool. A simple and efficient way to reduce the volume of noise by more than 70%.

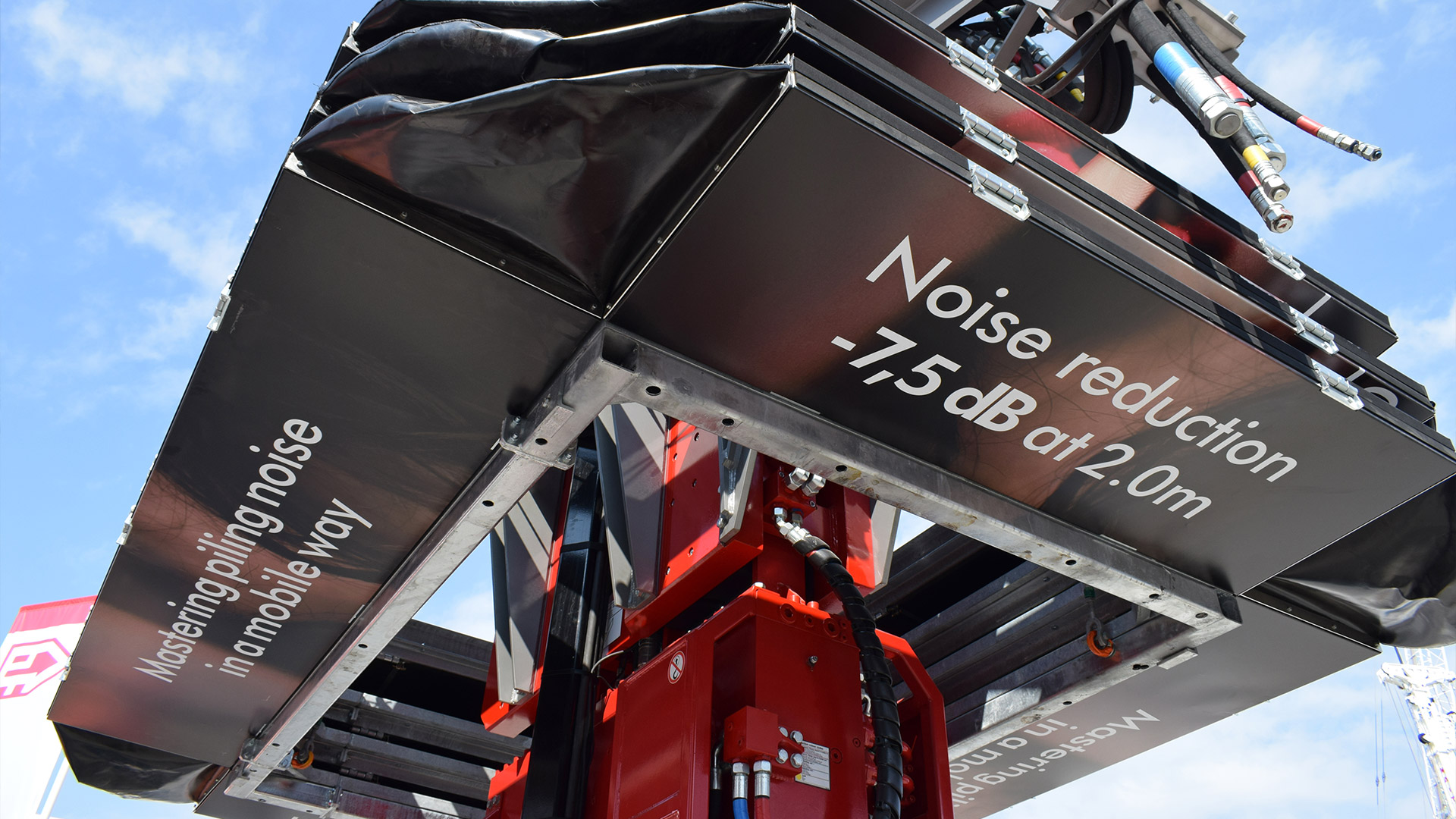

Noise reduction during Vibro-installation

Another source of sound is generated by the pile or casing during vibro-installation. The newly developed mobile Noise Reduction Screen (NRS) that drapes around the profile, and that is mounted to the Vibratory Hammer, protects the environment against noise pollution by lowering and raising foldable acoustic panels. The damping value is -/-7.5 dB at a 1-meter distance, which means a noise reduction of approximately 80%.

The result of -7,5 dB damping is a noise reduction of 80%

Noise Reduction Screen (NRS)

The Noise Reduction Screen is a Dieseko Group Innovation. We offer a foldable, mobile solution applicable for vibratory hammers driving tubes and sheet piles, which enables our clients to continue working by staying inside noise restrictions.

Watch here some footage of the test:

Last year we achieved a top 3 position in the Industry Innovations category of the 2020 VDBUM Förderpreis (Innovation Awards) for the Noise Reduction Screen.

This Noise Reduction Screen can significantly reduce noise pollution on the construction site. It is one of our solutions in the field of emission and sustainability. We are now fine-tuning the technical concept and, constructing and testing a prototype with a height of approx. 21,0m.

General specifications

Rob Eijkens

Technical Manager Offshore

Jos Hardeman

Senior Sales Area Manager - Mid-Europe, Scandinavia, UK