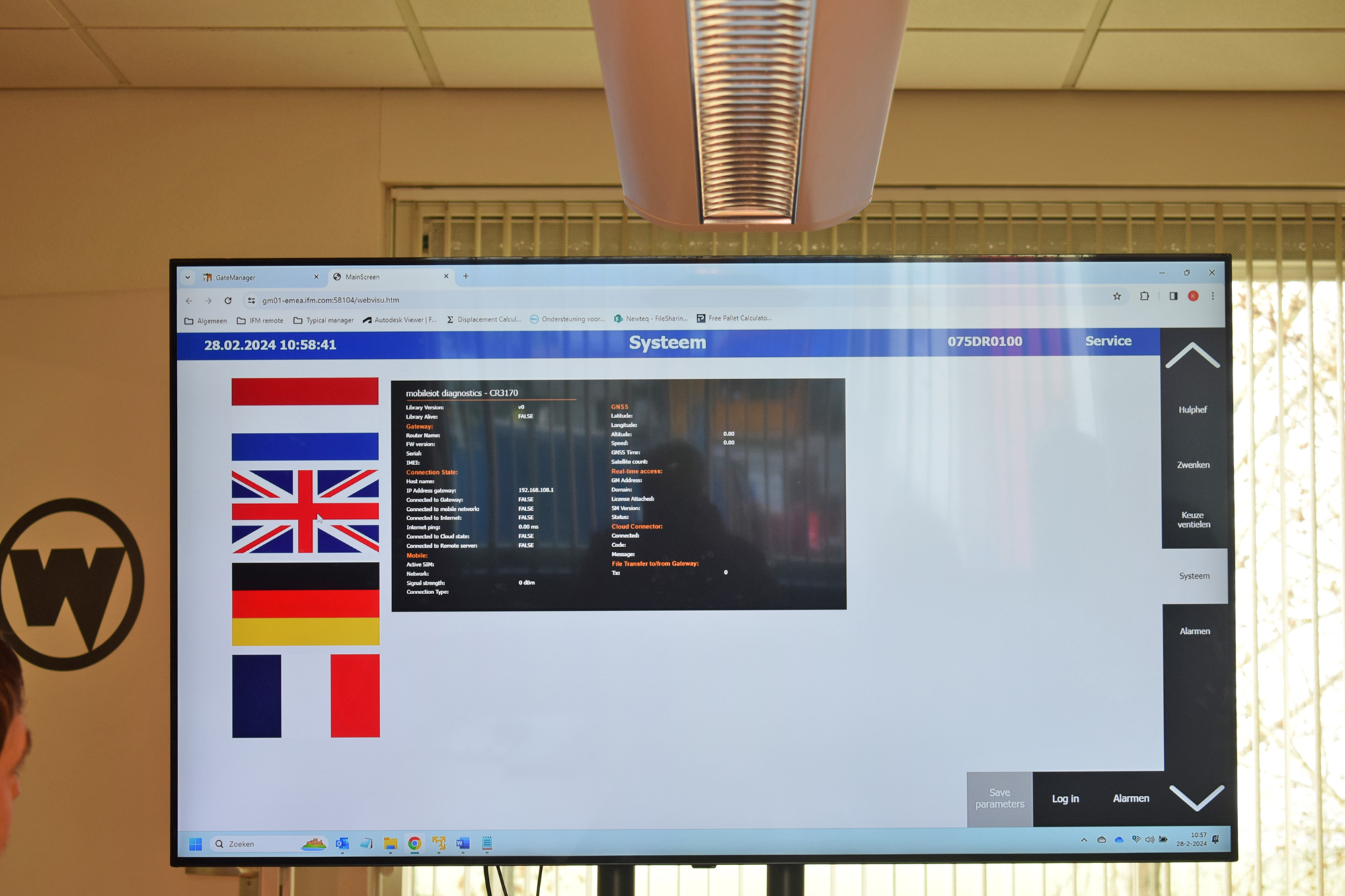

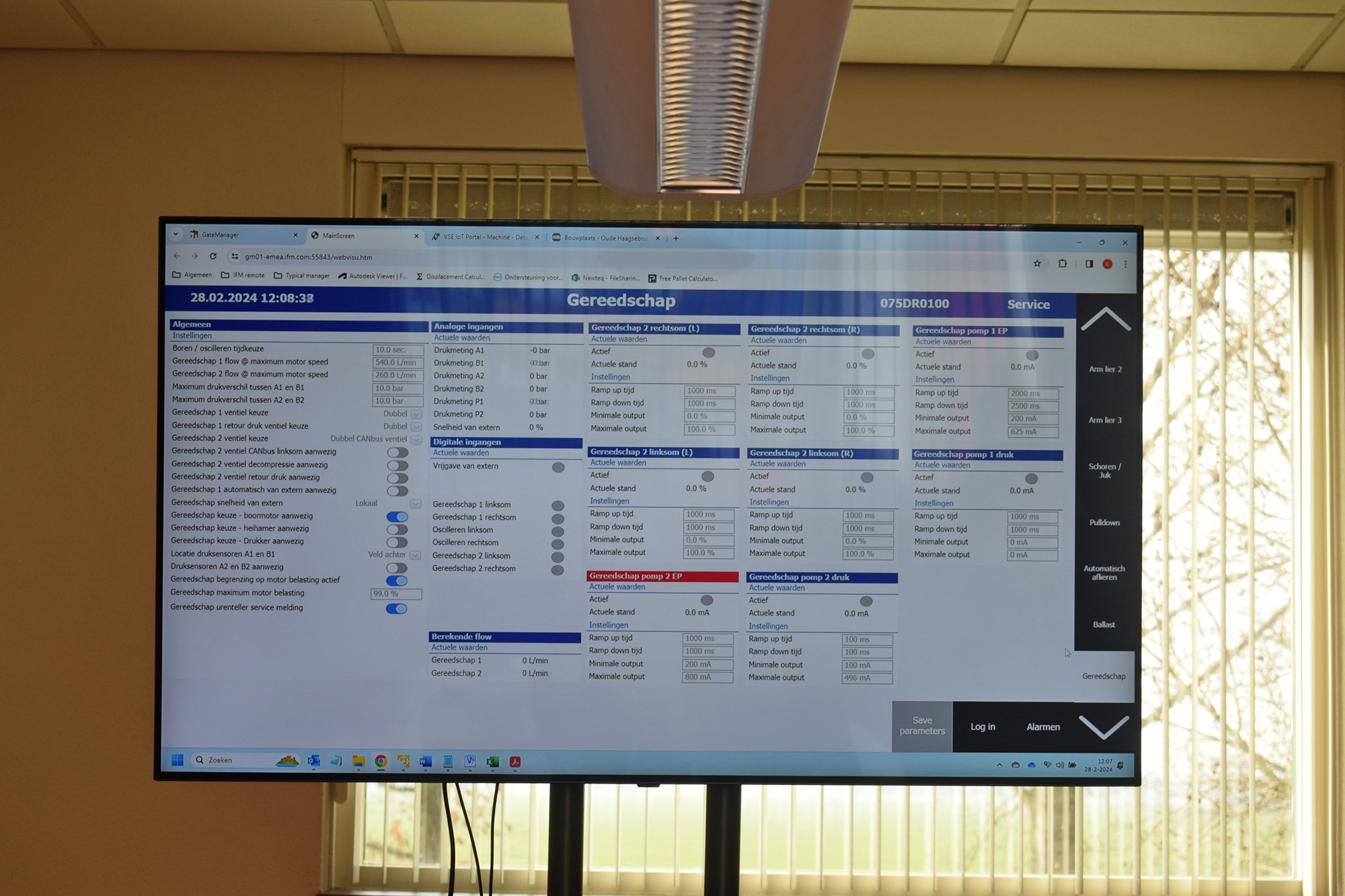

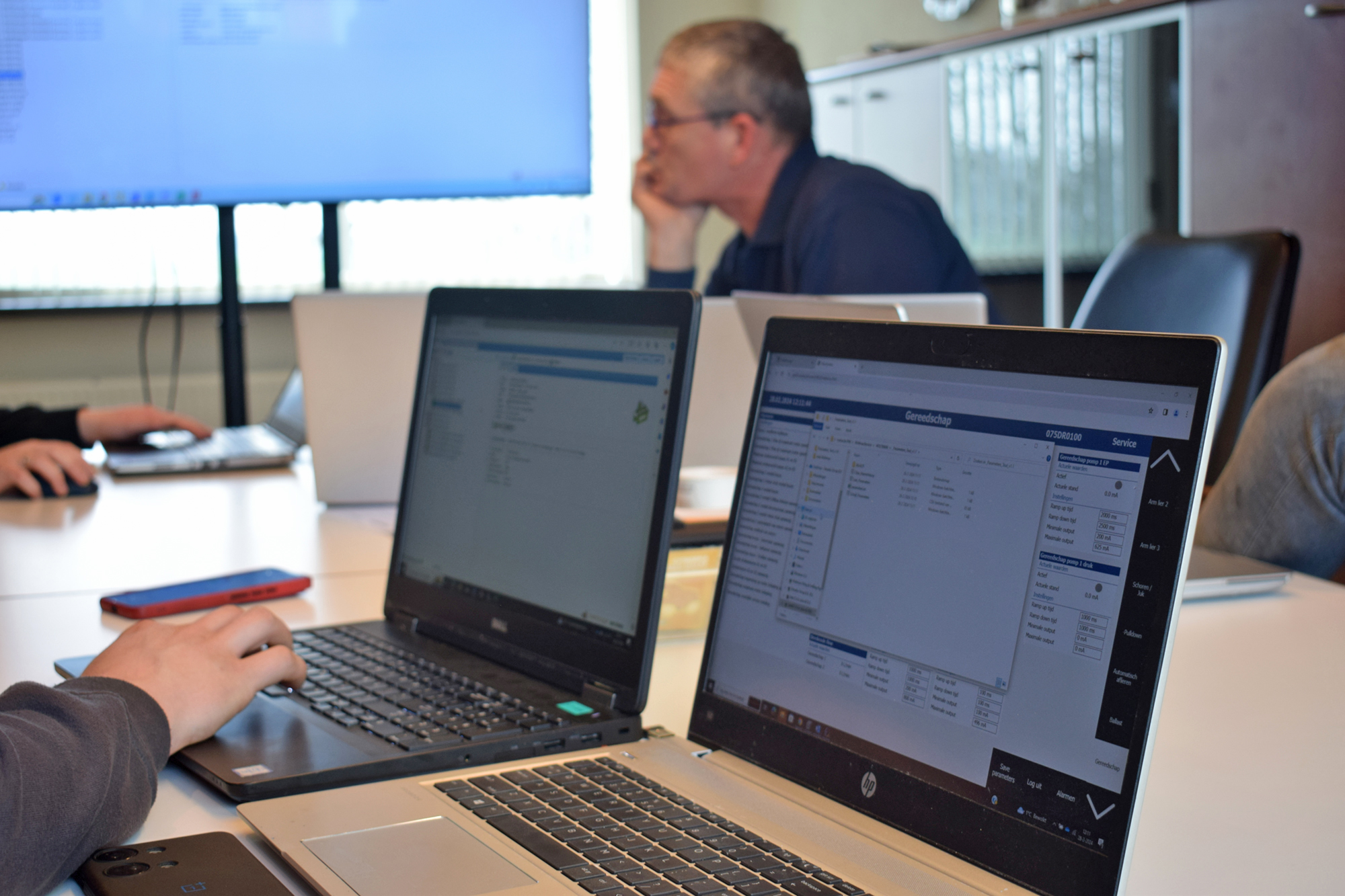

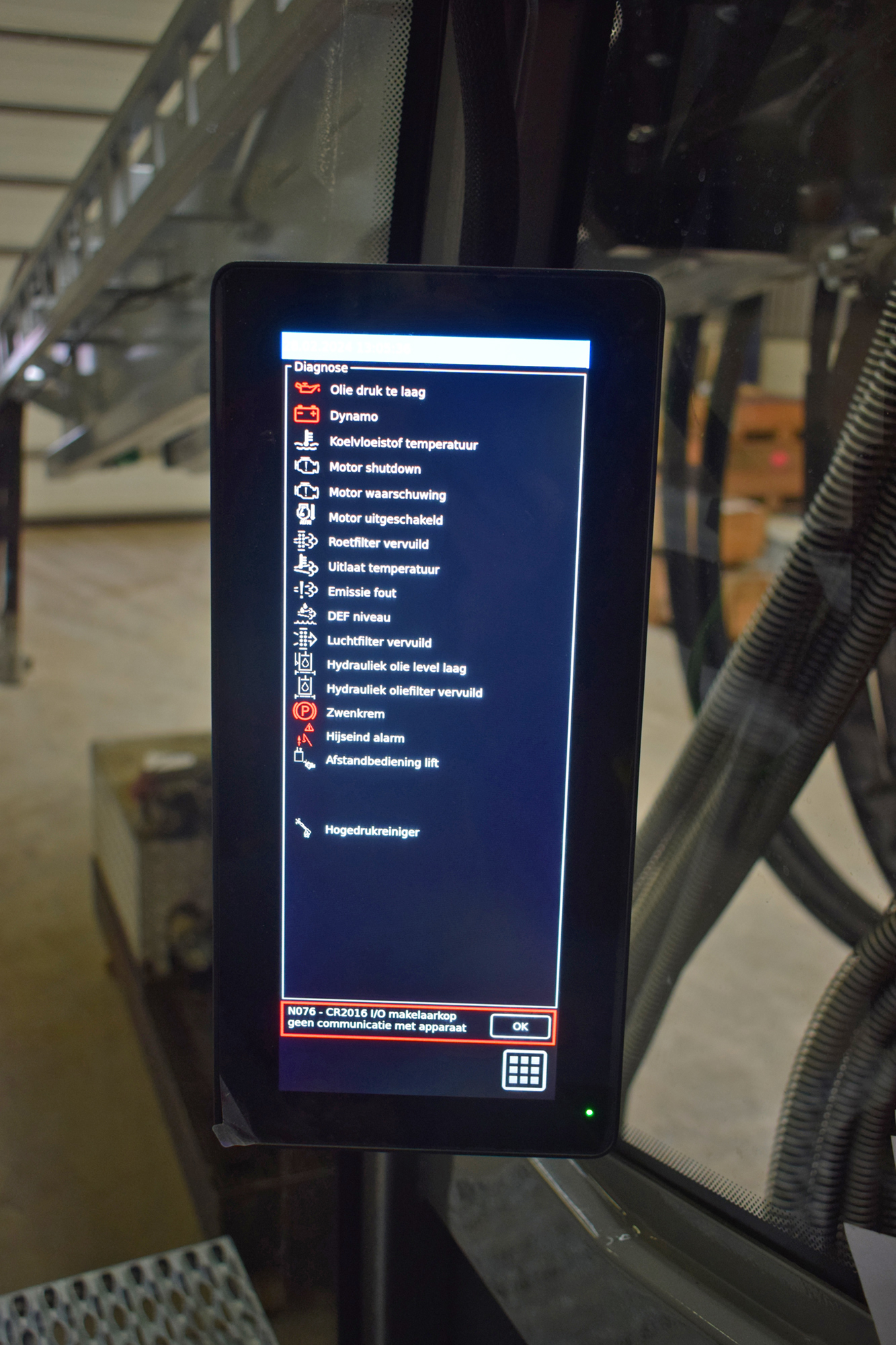

Besides the fact that this control system is easy to use, remote service is also possible. In the event of a malfunction, it can often be repaired remotely, with or without an operator. This greatly reduces machine downtime. Woltman’s suppliers have also contributed to improved remote service. Fault codes for valves, pumps and motors, for example, have been transferred one-to-one. This means that faults in externally manufactured parts can also be quickly identified. If necessary, the right person can be contacted quickly.