Woltman Piling & Drilling Rigs is a specialist when it comes to foundation and ground improvement equipment. The state of the art Woltman Piling & Drilling rigs are sophisticated and developed according to the latest technologies. The rigs are designed in such a way that they can be easily operated and serviced in an efficient and safe way.

The high efficiency of Woltman Piling & Drilling Rigs is achieved by its reliability and high standard materials and parts such as powerful engines and hydraulic systems. Woltman offers solutions for nearly every foundation and ground improvement technology.

- Safe working A perfect fit for less sensitive, heavy duty jobs

- Extensive range from 30 to 160 tonnes

- Designed for the job Can be used for onshore, harbour and offshore projects

The Woltman piling and drilling rigs are developed according to the latest demands for performing traditional piling works as well as the latest piling and ground improvement technologies. Besides the ability for excellent performance for piling and drilling operations, the rigs also meet the latest environmental requirements such as efficient use of fuel and meeting emission standards. The Woltman piling and drilling rigs are suitable for every challenge in the field of foundation technologies and ground improvement.

product

Woltman 90DRe Electric Drilling Rig

0

different

Rig types

0

perfect combination

with PVE atachments

0

places in the world

for selling and servicing Piling & Drilling Rigs

6 reasons to choose a Woltman Rig

- Designed for the job

- High mobility increasing cost effectiveness

- Excellent stability ensures suitability for every jobsite

- High efficiency by reliability

- In house manufactured accessories

- Woltman’s long experience and wide product range

Designed for the job

The Woltman rigs are especially designed for piling operations and ground improvement, which makes them unique compared to other machines available on the market. The contribution of decades of experience in the foundation market is well implemented in the in-house development and design of our rigs.

High mobility increasing cost effectiveness

The compact size of the of the smaller range of Woltman rigs enables the machines to work in areas with limited access. Their excellent mobility enables our clients to minimize mobilization and demobilization as the compact rigs are erected and lowered in only minutes. The rigs are equipped with a self-erecting leader which reduces the time of assembly considerably.

Especially when it comes to the installation of raked piles the PDS rigs prove their point. With help of the outriggers that are mounted to the rear of the boom of the crane, bigger rake positions are achieved and less working space is required compared to traditional pile driving installations. The PDS rigs can be used onshore but also near-shore on a barge, pontoon or Jack up barge. Woltman offers different models of which the PDS 1000 and 1200 are still easy to transport by a low-boy trailer. The PDS 3000 is designed more specifically to work permanently from a barge or ship for near-shore and harbor works.

Excellent stability ensures suitability for every jobsite

The Woltman rigs are designed with a wide undercarriage and low center of gravity which provides high stability and makes the piling rigs suitable for every jobsite.

High efficiency by reliability

The high efficiency of Woltman piling rigs is achieved by the powerful engine and hydraulic system. Woltman only uses top quality parts for its rigs such as Caterpillar and Cummins engines and Bosch Rexroth hydraulic pumps and parts.

In house manufactured accessories

Woltman piling and drilling rigs are multipurpose by the possibility of equipping the rigs with all kinds of in house manufactured accessories. Woltman | Dieseko Group develops and supplies its own impact hammers, vibratory hammers, ring vibrators, vibroflots, resonators, pressing machines, power packs and much more. Because all accessories are manufactured in house, the best possible and most reliable configuration is achieved for the job. Of course all Woltman rigs can also be equipped with other brands of auxiliaries.

Applications

- Full Displacement Drilling

- Semi Displacement Drilling

- CFA Drilling

- Double Rotary Drilling

- Piling (precast piles, steel tubes, timber piles, beams)

- Vibrated Micro Piles

- Vibrated Sheet Piles

- Pressurised Sheet Piles

- Resonated Piles

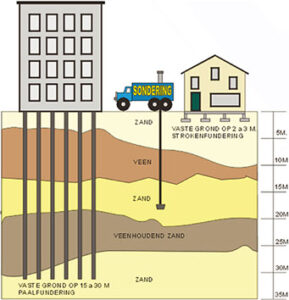

Principle of pile foundations

A pile foundation is necessary when the loads of a building will be higher than the upper soil layer can take. Piles are installed primarily to avoid settlements which could result in big damages and dangerous situations. In a limited number of projects piles are installed as ‘tension’ piles these are installed to prevent the object from lifting out of the ground. A well-known example are piles installed under the high tension electricity piles. Due to high forces created by wind the piles need to be ’anchored’ in the ground.

Soiltype versus pile type

There are many different piles and piling methods. Some of the methods are very efficient in the weaker soils but can’t be executed in hard soils. In some cases for example when building a sky scraper it is necessary to install piles in to hard rock as well. The methods for this are rather limited.

Soil investigation

To come to the best design of a pile foundation it is absolutely necessary to have a good report and investigation on the ground conditions where the jobsite will take place. A good report and inspection will minimize the risk of unexpected delay and additional costs. In Europe the system in which a cylinder is pushed into the ground to determine the soil type and friction is very popular in most parts of the world the so-called SPT (soil penetration report) is made. In this case little amounts of soil are excavated to determine the type of soil which can be encountered when installing piles. PVE does not supply soil investigation equipment but for the vibratory and impact hammers there are special prediction programs available which can help to determine the driveability of certain sheetpiles and casings in different ground conditions.

Pile driving

Precast concrete piles (manufactured in a concrete factory) in most cases square but there are also countries where these piles are octagonal or round and even hollow.

Woltman Piling & Drilling Rigs with PVE attachments.

Drilling Rigs

Woltman Drilling Rigs rigs are specially designed for high torque drilling methods as displacement drilling and big diameter CFA.

- No excavator or crawler crane is used as undercarriage which has made it possible to guarantee the highest possible stability and low centre point of gravity.

- All Woltman rigs have a solid and strong undercarriage which is hydraulically extendable and is fitted with wide track plates.

- The winches of the Drilling rigs are fully synchronized in pull-up and pull-down operation.

- Lots of accessories available to enable multipurpose operation.

Drilling methods supported by Woltman

Semi Displacement Drilling

- Piles are cast in situ

- combination of CFA and displacement technology

- Wider core of the auger for a strong displacement effect

- Spirals on the side for the upward movement of the soil.

- Concrete or gravel is added through the centre of the drill

- Used when the soil is too weak for a normal CFA pile

Continuous Flight Auger (CFA) Drilling

- CFA piles are cast in situ.

- Fast method to replace the soil for concrete in one continuous operation

- At the desired depth, concrete is pumped through the centre of the auger

- After extraction of the auger, reinforcement is installed

Full Displacement Drilling

- Classic method for cast in situ

- Zero vibrations

- Best bearing capacity due to compacted soil and reinforcement

- Combi-pile: usage of precast octagonal core

- Near industry or in urban area’s: no soil is taken out

- Lost Drill Tip method: after drilling and retraction of the tube, the tip remains

- High torque and a high stability rig is needed

- Woltman is specialist in equipment for this type of foundation

Double Rotary Drilling

- A cased auger method mostly used to install concrete secant pile walls

- These retaining walls constructed to hold the ground and / or obtain water tightness prior to excavation

- Fast and cost effective installation method

Piling Rigs

The purpose-built Woltman Piling Rigs are specially designed to drive piles.

- A thoughtful design, equipped with the most modern measurement tools and accessories

- The undercarriage guarantees the highest possible stability and a very low centre of gravity.

- The solid and strong undercarriage is hydraulically extendable and is fitted with wide track plates.

- The winches of the Woltman machines are synchronized in a sophisticated way to ensure the most efficient pile driving operation.

PDS Piling Rigs

Woltman offers heavy pile driving machines that can be used as a regular lifting crane as well. The unique design requires a lot less working space compared to conventional crawler cranes with a hanging leader. The range starts at 100 tons class up to 300 tons.

- All PDS rigs have a patented design which offers the perfect solution for projects in which pile driving and lifting work are combined. The PDS rigs can be used as a normal HD-crawler crane or as a pile driver with leader lengths up to 60 meters.

- With help of the outriggers that are mounted to the rear of the boom of the crane, bigger rake positions are achieved and less working space is required compared to traditional pile driving installations.

- The PDS machines can be used onshore but also offshore on a barge or pontoon.

Want our expertise? Connect with us

Christian de Heus

Sales Manager Woltman