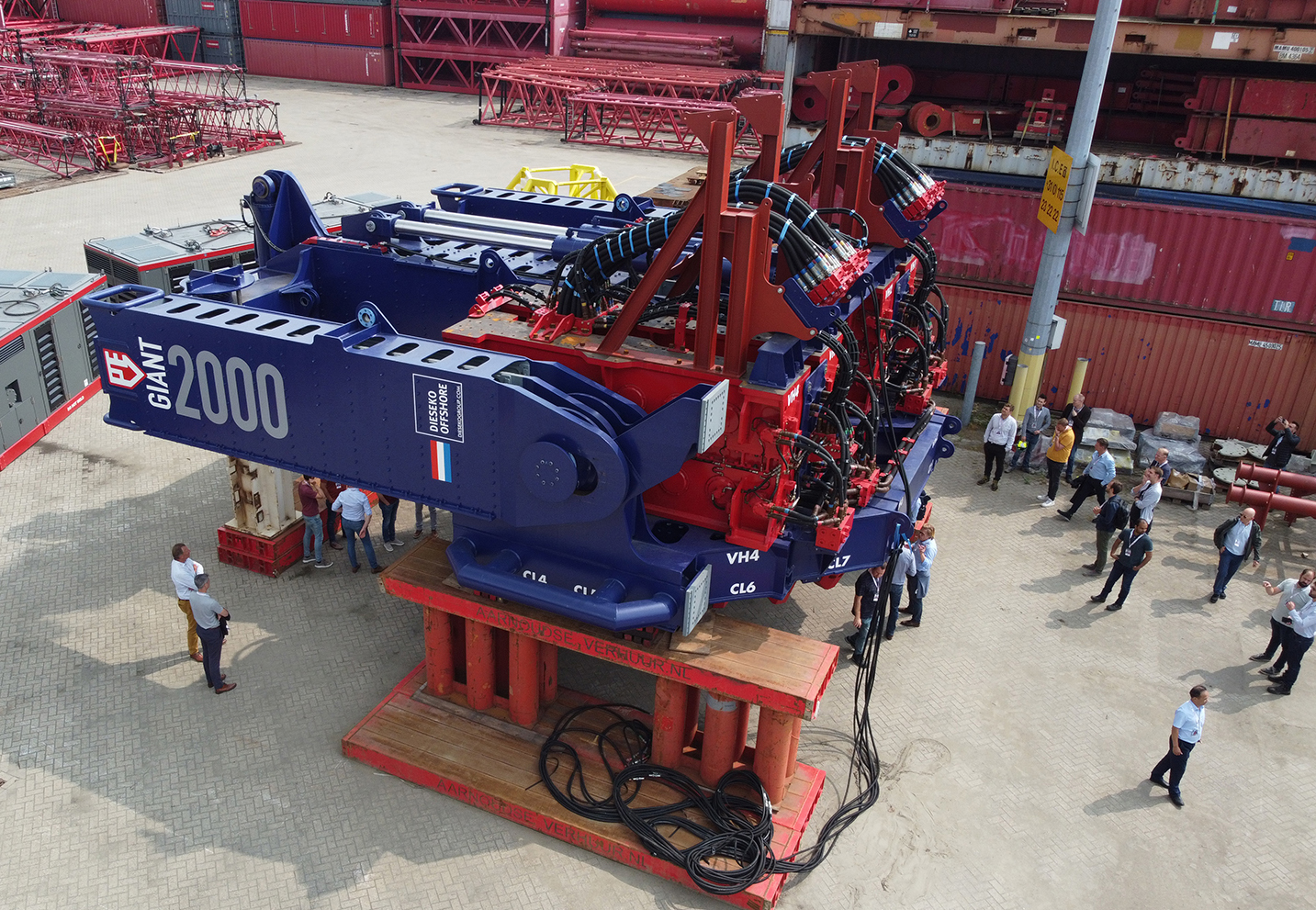

The hose reels are responsible for transferring the correct hydraulic oil flow and pressure to the dynamic environment where our GIANT operates. The hose reels ensure efficient and safe hose management. This is the reason Dieseko Group recently tested four hydraulic hose reels simultaneously for the operation of our GIANT 2000 Vibratory Hammer.

Absolutely synchronous

It is crucial that all hose reels work together in perfect synchrony, whether they are paying in or paying out, and that they are configured as a master-slave system. At the same time, it should be possible to make individual adjustments without disrupting the synchronization between the hose reels. Additionally, they must be pressure-tight, apply the correct tension, and respond fail-safe in case of emergencies or malfunctions.

Operational readiness

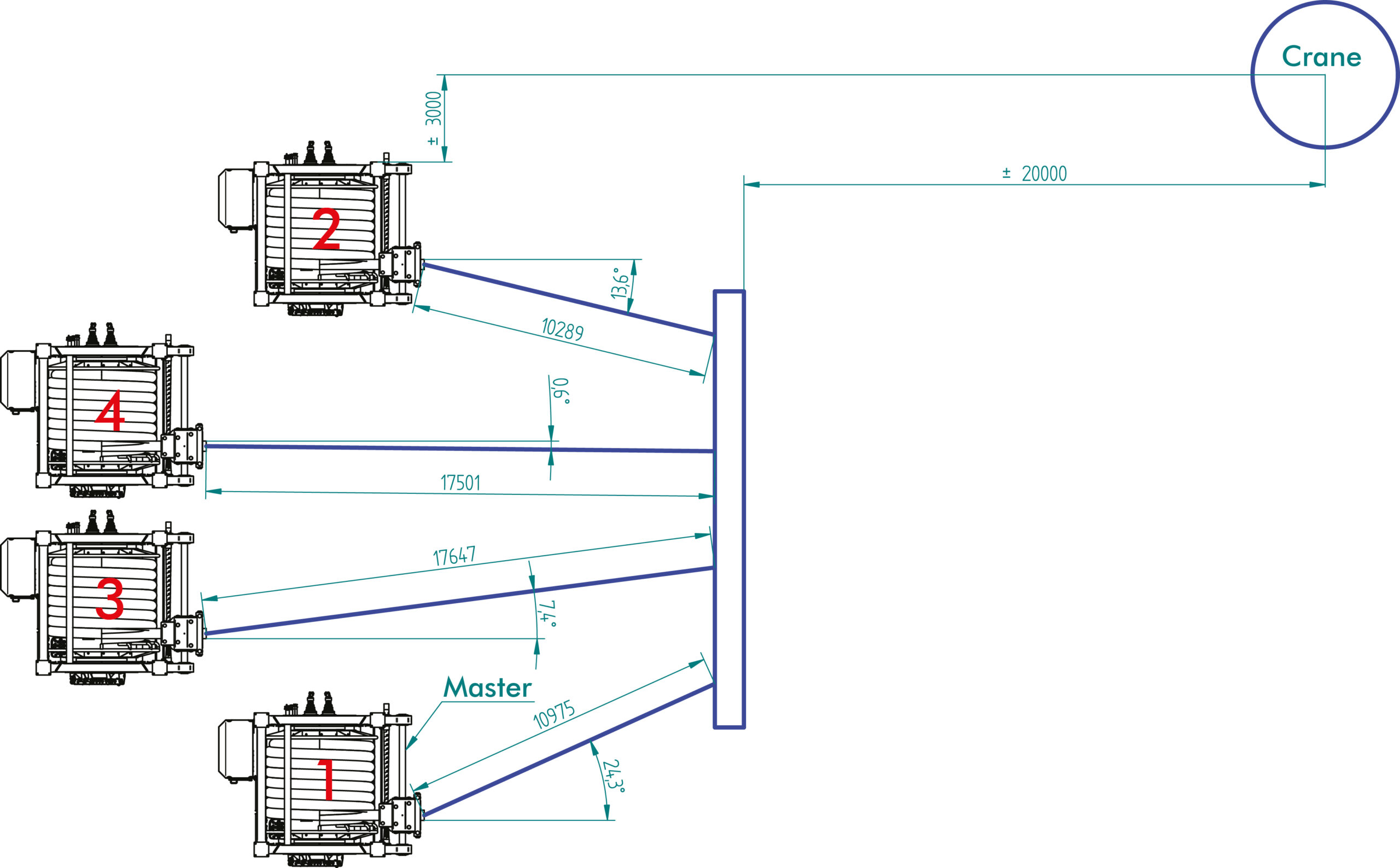

Tests were recently conducted to test the operational readiness of a hose reel system, in order to prepare for offshore use. The test simulated real project conditions as closely as possible. The reels were positioned in the same way as they would be on the vessel, and the hose ends were connected to a spreader bar, which created different payout and pay-in angles that would also occur in real operations. Different redundant operation modes were also tested, including remote-controlled, HMI-controlled, and emergency-controlled modes.

The hose bundles of all the four hose reels roll out nicely in sync.

Test results

The tests have shown hundred percent functionality after hydraulic and software adjustments and have provided useful insights for safe and efficient operation on board our client’s vessel. These tests have shown that using thoroughly tested programs can further develop offshore expertise when operating our XXL vibratory hammers. We are thrilled to utilize this new equipment in its first offshore campaign.

In summary, the tests were performed with great care and attention to detail, and the equipment has passed with flying colors. This once again demonstrates that Dieseko is a reliable partner for offshore operations.

PVE GIANT 2000 Upending Vibro

GIANT 2000 gets attention @ OEEC2022 show

GIANT event Westdorpe

WANT OUR EXPERTISE ON THIS TEST OR THE GIANT ? CONNECT WITH ME!

Rob Eijkens

Technical Manager Offshore