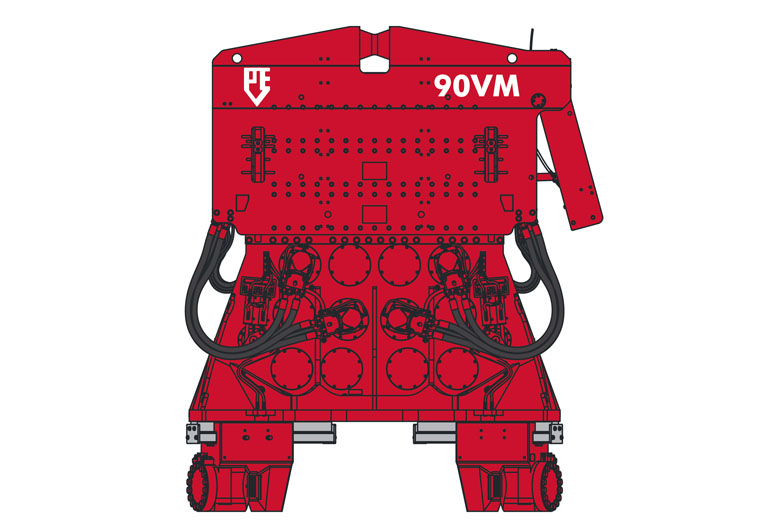

This pipeline is welded on land and placed on the seabed as one long tube. A 1,000m stringing location on the Jutland-side has been used for welding. On the Funen-side the pulling construction was located. With the PVE 90VM, five guide piles and one wire guidance pile were installed to bend the Baltic gas pipeline underwater. To protect vulnerable marine life from any harm, the Resonance Free start and stop of the Variable Moment technology was used. Vibrating piles is a time-saving and, the lowest-emission method to date. A bubble screen was used for security to keep seals at a safe distance. We’re proud to be part of this impressive project. The PVE 90VM was rented out by our dealer Lesanco to the subcontractor Arkil.

Sizes of the tubular piles:

- 5 x guide pile with rollers (ø 1420mm – 8,5m penetration depth).

- 1 x wire guidance pile (ø 1420mm – 13,5m penetration depth).

Yes please, tell me more about this project

Robin van Lingen

Rental Manager

PRODUCTS FEATURED IN THIS PROJECT:

PVE 90VM