The 170NF is attached to this leader on a piling vessel. The pile weight exceeded the line pull of the 170NF tandem, so the hammer rested on the top of the pile. When I was there was a pile-run, the pile shot down about 6 meters, and the hammer which was resting on top of the pile went down with it. The sudden jolt created when the pile reaches a firmer soil layer probably made the elastomers work very hard and it resulted in the need to replace some broken elastomers after the conclusion of the project.

Location

The coast of Fujian Province.

Equipment

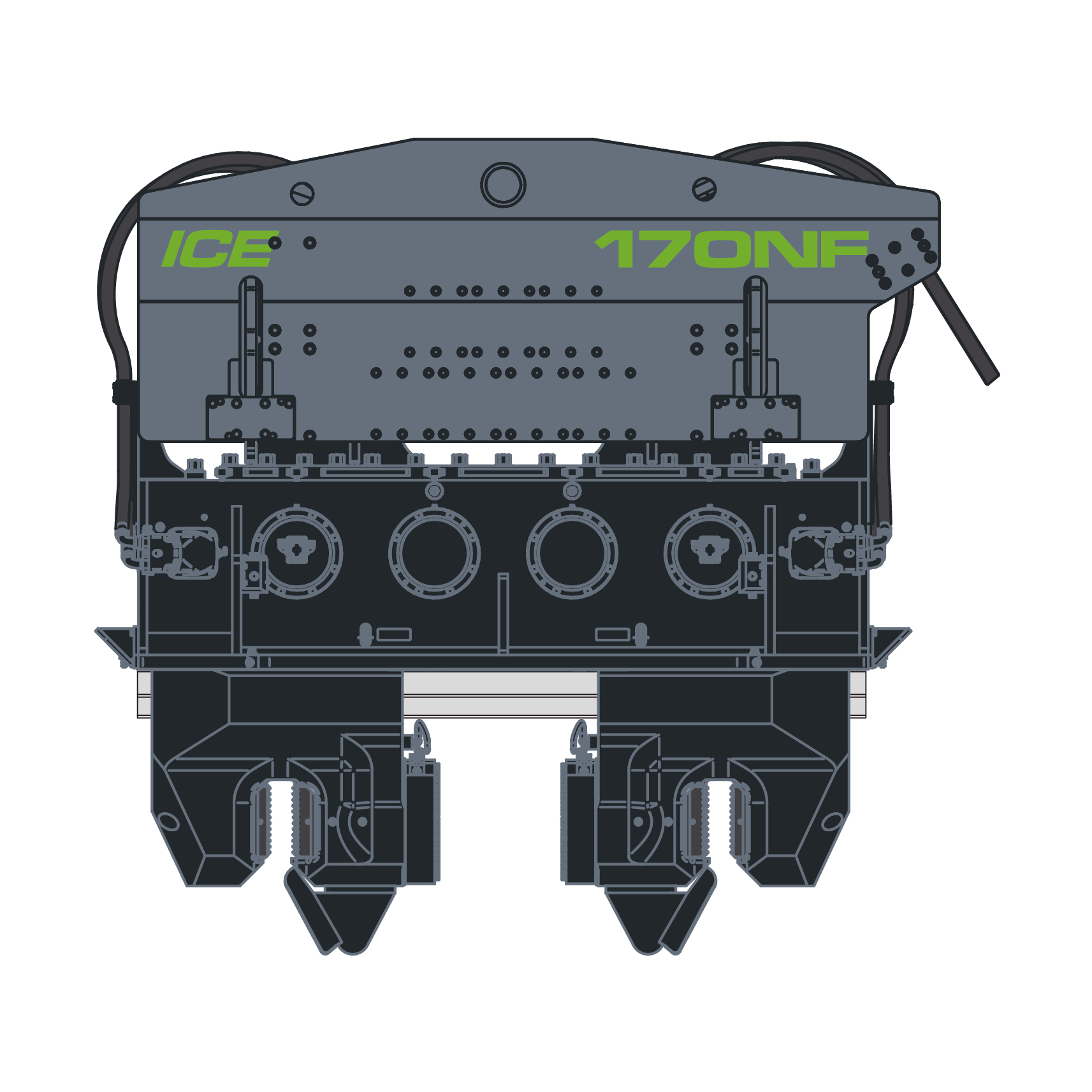

ICE 170NF Twin Vibratory Hammer & 2 ICE 1400 Power Packs

Works

Driving 94m long, 4.4m diameter casings

Executor

Zhejiang Communication Construction Group

Why bigger vibratory hammers aren’t always better is easily understood:

A vibratory hammer is made up of two parts: a dynamic vibrating part (the gearcase, clamps, 50% of the weight of the elastomers) and the static weight (the yoke and the other half of the elastomer weight). The heavier the dynamic part the more eccentric weight is used up by moving the dynamic weight and less remains to create amplitude to liquefy the soil. This tends to create a vicious cycle of ever increasing weight to create more amplitude. That is why ICE is so focused on right-sizing the hammer recommended for each job as it will give the best piling result.

This project clearly demonstrated the selling points of ICE vibro equipment. The 170NF’s light weight is also much easier to handle for the contractor, smaller lifting equipment can be used, and energy consumption is also greatly reduced. If you are not a regular ICE user yet we recommend that for your next project you choose an ICE hammer as well!

ICE 170NF

Eccentric Moment

From 0 to 170 kgmMax. Centrifugal Force

From 0 to 3654 kNMax. Frequency

1400 rpm

ICE 1400 Volvo STAGE – / TIER 3

Engine/Motor

VolvoMax. Power

820 kWOil Flow

1476 l/minI can tell you more about this project and the equipment used.

Arjen van der Schoot

Managing Director Shanghai ICE