The Kinmen Bridge will connect Greater Kinmen Island and Lieyu Island just off the coast of Xiamen. The bridge will link Jinning Township on Greater Kinmen Island and Lieyu Township on Lieyu Island. It will span over 5.4 km in length and will be supported by five towers, each with separation distance of 280 meters. The bridge surface will have 15 meters width, which will consist of two lanes for vehicles, one lane for pedestrian, and one lane for bicycle. The project was approved by Council for Economic Planning and Development on 28 February 2010. The bridge construction commenced in 2013. On 29 June 2016 the construction work was suspended when the government terminated the contract of the construction company who had been building the bridge due to their poor construction management which had caused the project to be seriously behind schedule.

In Augusts 2016 the Taiwan Area National Expressway Engineering Bureau invited new contractor companies to complete the remaining project. The bureau announced Dong Pi Construction Co. Ltd as the tender winner on 31 August 2016. Work has now been resumed and the bridge is now expected to be completed by the end of 2019.

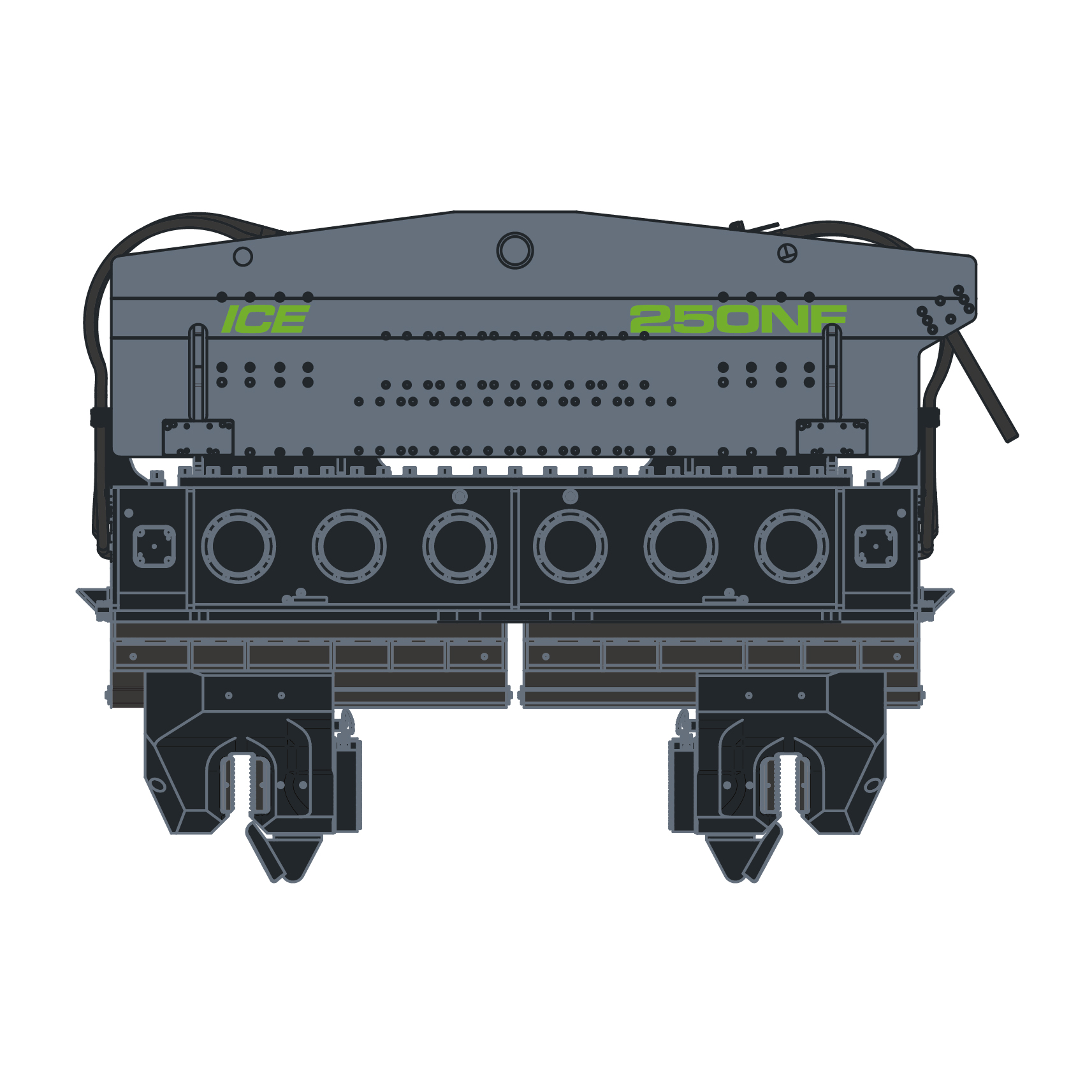

In early July the 250NF was installed with the assistance of the ICE Taiwan dealer Helpful Machinery and the ICE Hong Kong dealer Face Machinery China. The installation of the hammer consisted of bolting the beams to the hammer’s X-footplate and sliding the 4 clamps on. After opening the hydraulic locks that keep the clamps in place during driving, the clamps can be moved along the beam with a train wrench to adjust the clamping diameter. The 250NF that Dongpi ordered was custom built to have an internal X-plate allowing four clamps to be directly bolted to beams fixed to the bottom of the hammer; this design saves a lot of dynamic hammer weight compared to a separate X-plate, leaving more driving force and amplitude for driving the pile to depth

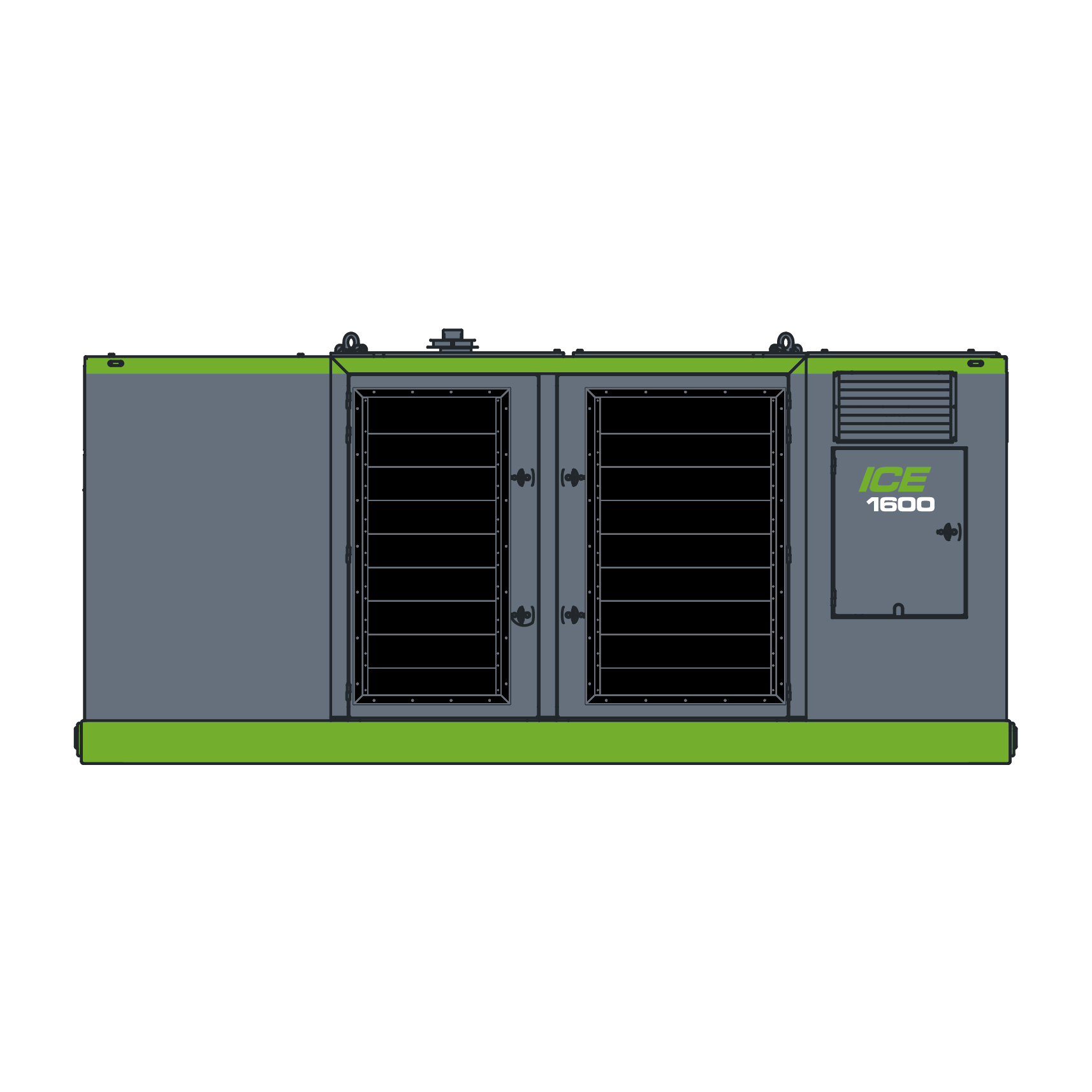

The 250NF is powered by the double Volvo engine 1600 power pack, it packs 1536 Horse Power which translates to 1600L hydraulic flow per minute for the hammer. Twelve 60m long hoses connect the hammer to the 1600 power pack, supplying oil to the hammer and clamps and bringing forced lubrication to the gears to ensure they never overheat during operation. The hammer operates from the Dong Ping No. 8 Barge which is equipped with a 190t crane. The massive crane allows for a great working range.

ICE 250NF

Eccentric Moment

From 0 to 250 kgmMax. Centrifugal Force

From 0 to 5374 kNMax. Frequency

1400 rpm

ICE 1600 Volvo STAGE – / TIER 2

Engine/Motor

VolvoMax. Power

1130 kWOil Flow

1665 l/minI CAN TELL YOU MORE ABOUT THIS PROJECT AND THE EQUIPMENT USED.

Arjen van der Schoot

Managing Director Shanghai ICE