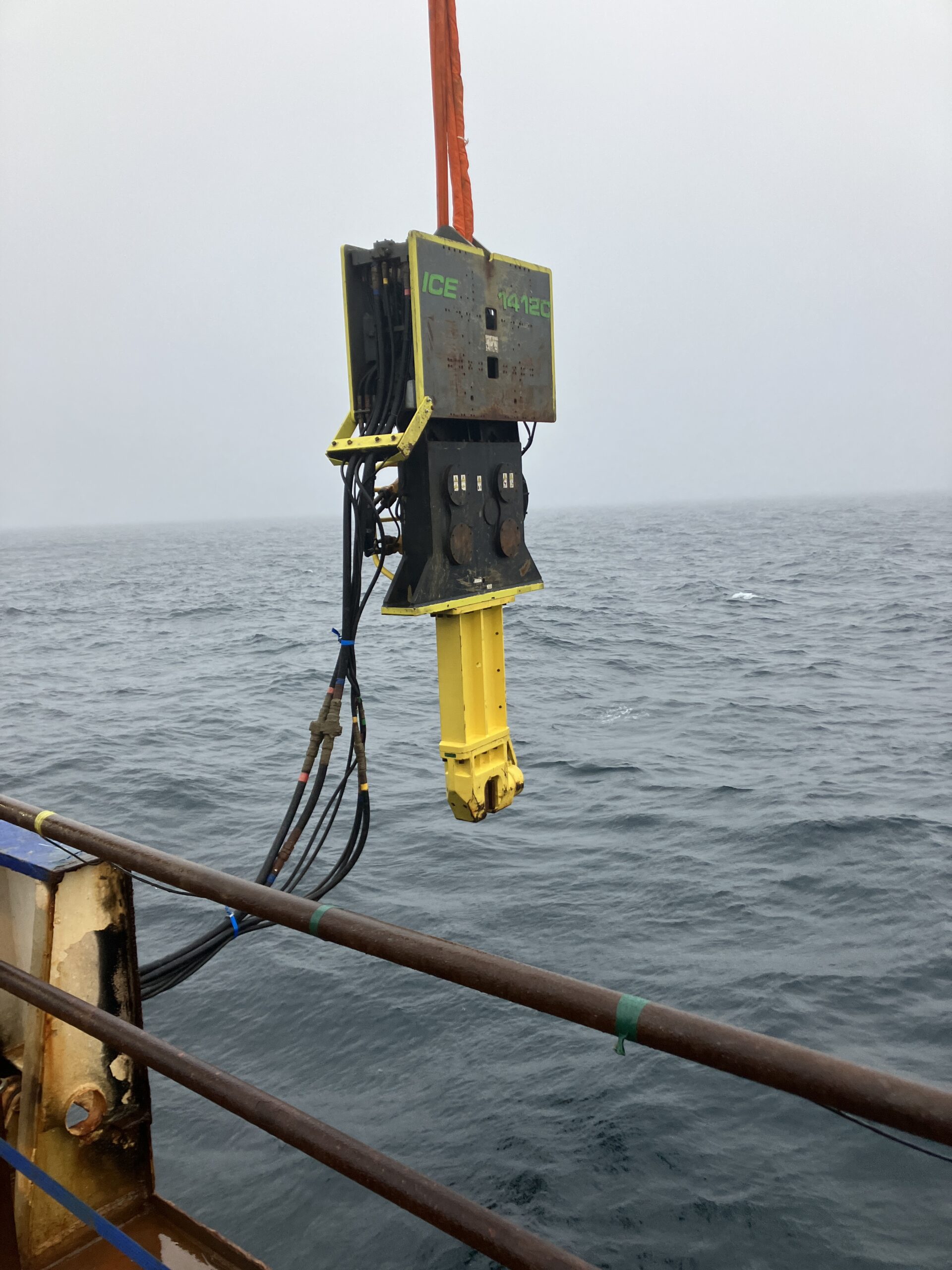

To connect the 1412C Normal Frequency Vibratory Hammer to the piles, we fitted an adapter piece between the vibratory hammer and the clamp. For subsea deployment, Dieseko equipped the Vibratory Hammer with a pressure regulator. Compressed air for the pressure regulator came from an external compressor on deck of the vessel.

Minimising residual damage

The main advantage of using a Vibratory Hammer to remove – pen – piles from the seabed is that the piles are completely removed to minimize residual damage. When cutting or sawing, part of the pile remains in the seabed.

Limited time

An additional advantage of extracting piles with a Vibratory Hammer is the limited time generally required for such a process. Depending on the type of soil, removal can be done in less than 15 minutes per pile.

For more information please contact:

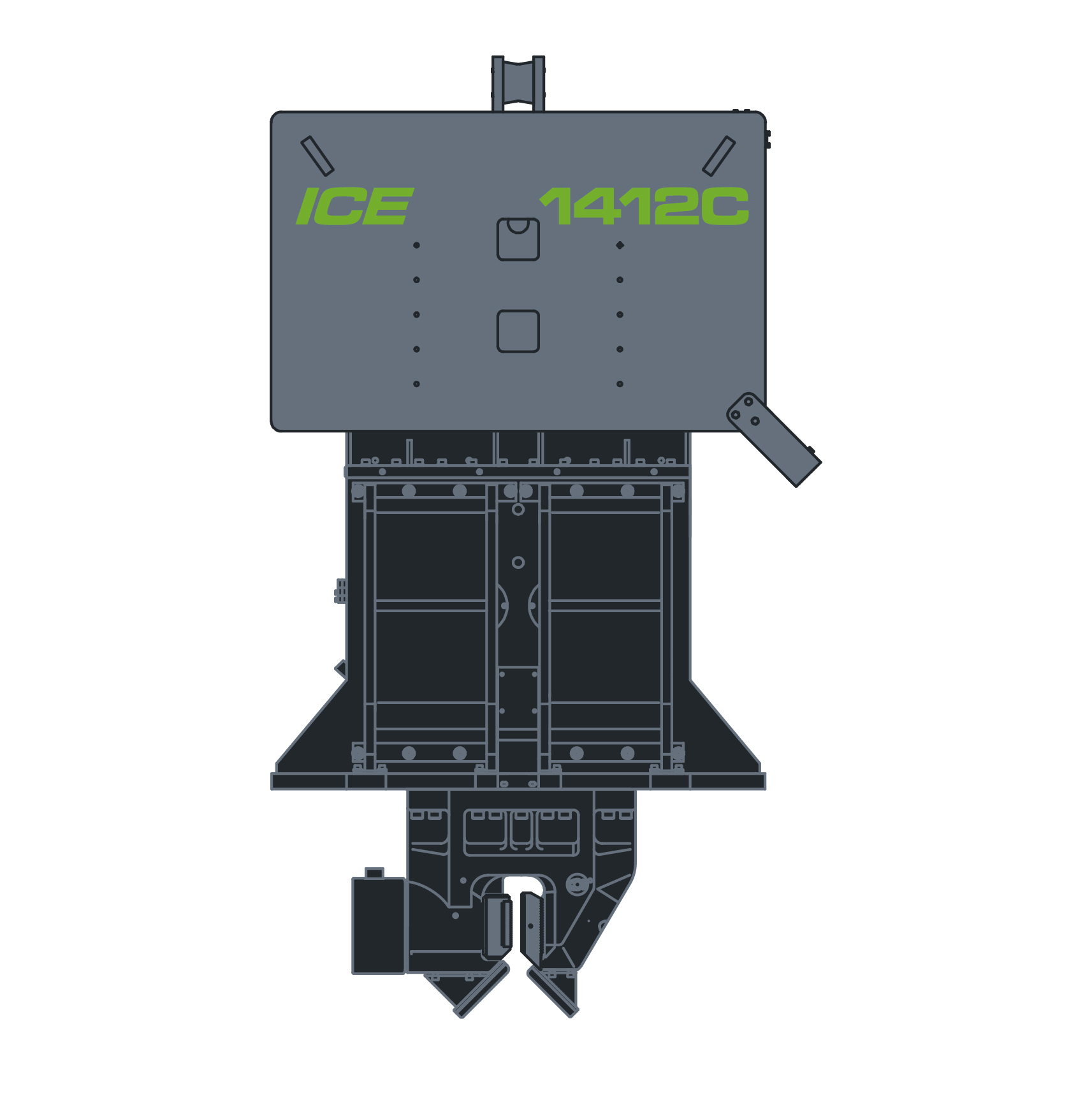

ICE 1412C

Eccentric Moment

From 0 to 110 kgmMax. Centrifugal Force

From 0 to 2300 kNMax. Frequency

1380 rpm