Decommissioning projects are an increasing proportion of the total number of offshore projects in the North Sea. Since the 1970s, the North Sea offshore oil and gas industry has become increasingly important to neighboring countries. Each field in the North Sea has different foundation structures, which were put in place at the time to meet the specific requirements of that field. As a result, the North Sea has many different types of foundations. Decommissioning all these different subsea structures is therefore a significant challenge. This is particularly the case for structures installed prior to the 1992/1998 OSPAR Convention, as decommissioning was not an explicit design consideration at that time. Current regulations require operators to dispose of installations once production or use of a facility has ceased. They are required to bring back the seabed in its original conditions and thus remove all components of the sub-sea installation.

Decommissioning

The project

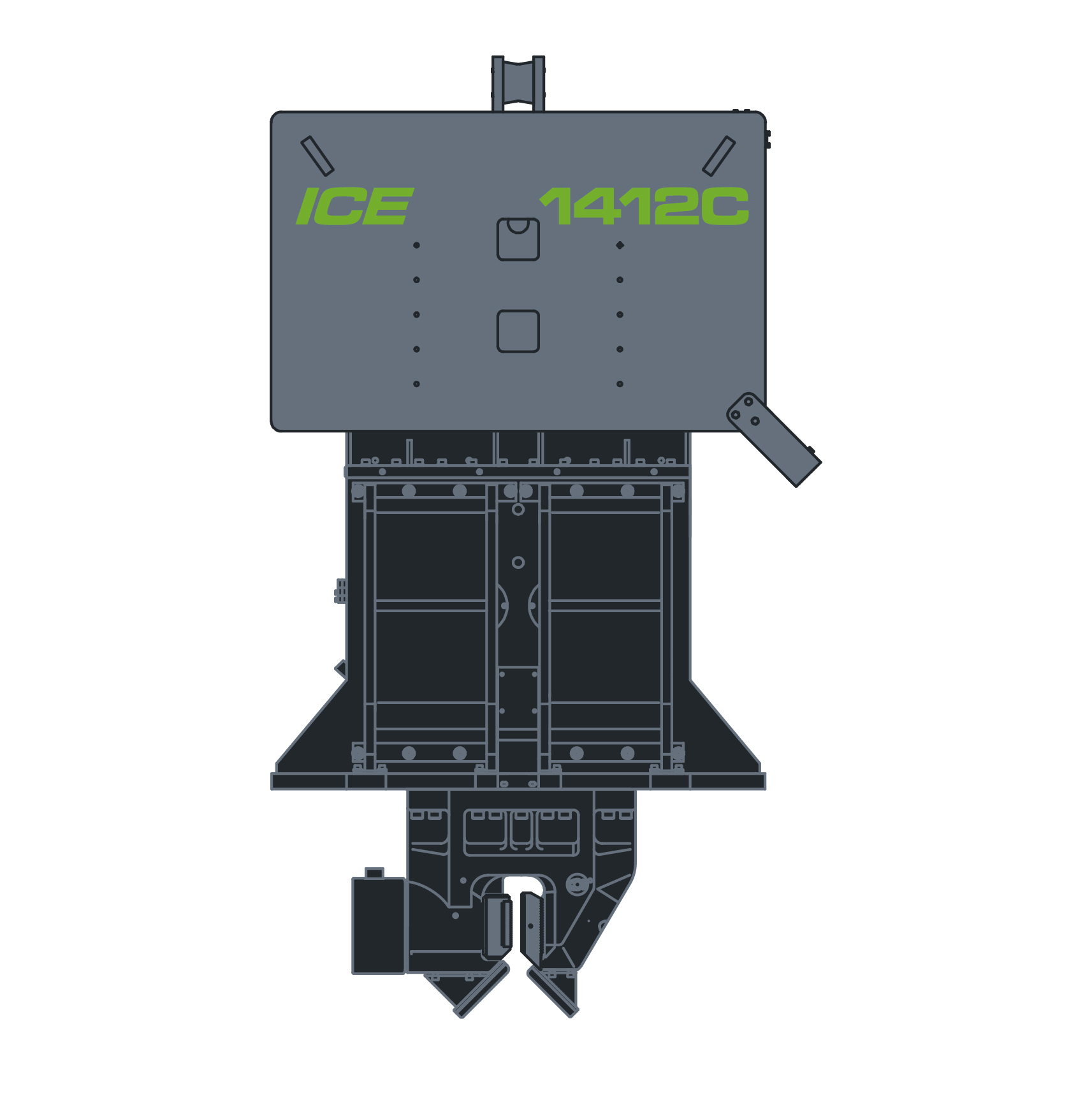

The project for which Dieseko provided the decommissioning involved the removal of four Anchortech A-shaped piles at each corner of a pigging skid structure in 36 metres of water depth. The Dieseko ICE 1412C vibratory hammer was used and removed all the piles in less than seven minutes each! This highly effective method greatly reduces the impact on the environment.

1412C Vibratory Hammer

The ICE Model 1412 is a high-quality variable frequency vibratory hammer/extractor designed primarily for driving and extracting larger foundation piles. Other hammers and special hydraulic clamps can also be used to drive or pull other heavy sections. The vibratory hammer can be used in different environments and is suitable for a variety of soil types. Each project requires the right approach and equipment.

Ask the Dieseko expert for advice and we will ensure that every project can be carried out in the best possible way.

ICE 1412C

Eccentric Moment

From 0 to 110 kgmMax. Centrifugal Force

From 0 to 2300 kNMax. Frequency

1380 rpm

ICE 900 CAT STAGE V / TIER 4F

Engine/Motor

CaterpillarMax. Power

563 kWOil Flow

972 l/min