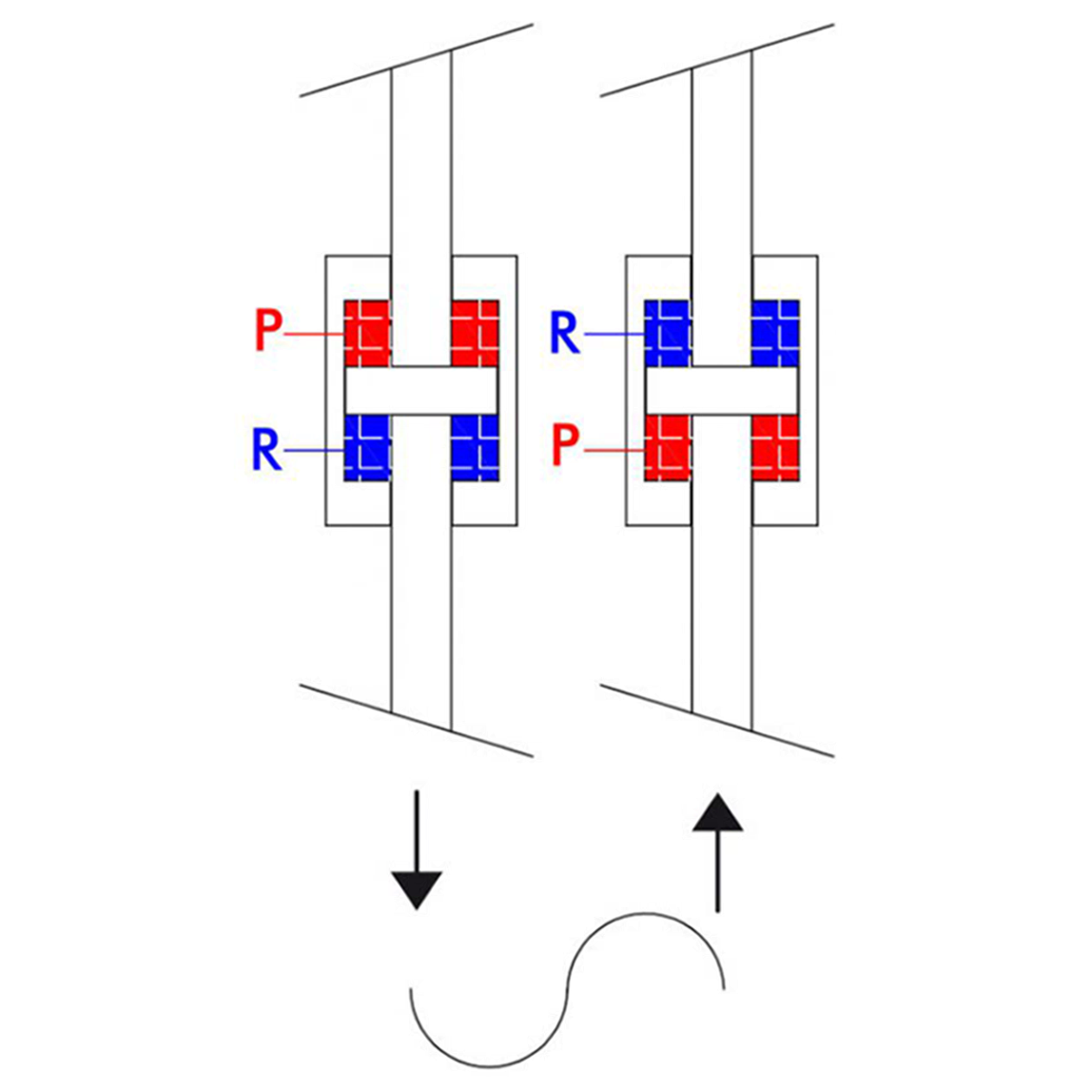

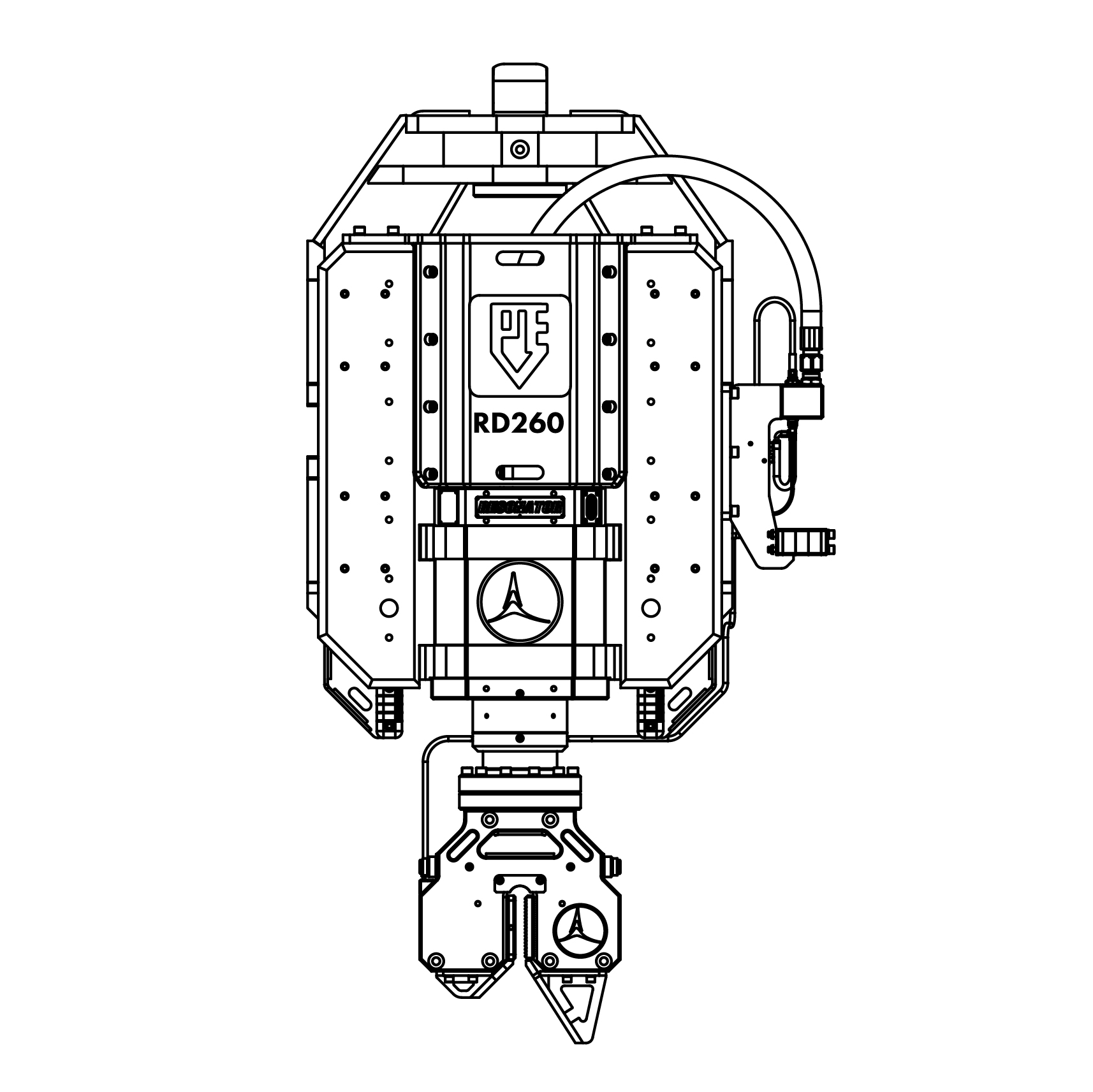

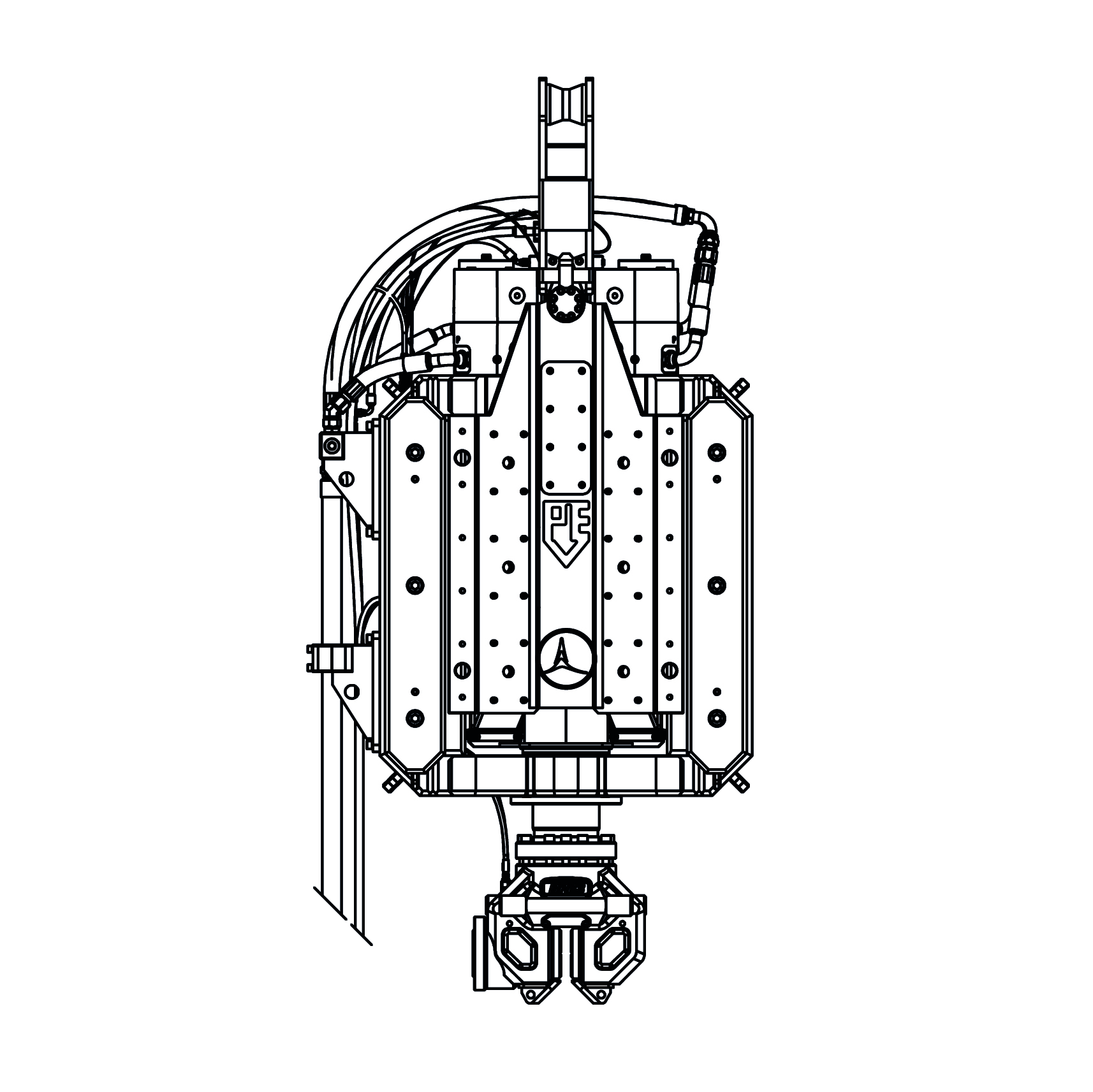

The Resonator uses patented pulse technology. Due to its high frequency, profiles are brought up to their natural frequency, which makes them behave like a coiled spring and drive themselves into the soil. Due to the lack of eccentric mass, this technology is completely vibration-free. The Resonator installs piles, pipes and sheet piles and can be used as a free-hanging, leader-guided or mobile-mounted crane.

Not a vibratory hammer

Vibratory hammers have been manufactured since the 1930’s and, since then, they have evolved in just a few steps to the current models. From electric to hydraulic hammers, from low-frequency to high-frequency hammers and from fixed to variable moment hammers. And now, with the introduction of the resonance technique, it’s time for a new step. The Resonance Driver can no longer be called a vibratory hammer, because it no longer works on the basis of eccentric mass. The resonance technique is a cylindrical principle operating at a very high frequency from 100 to 180Hz (6000 to 10,000 rpm), the so-called ‘resonance’.

Efficient

Compared with this new resonance technique, a great deal of the energy produced by the current generation of vibratory hammers is lost. This happens because a relevant percentage of the energy generated is used to make the soil move during the vibratory process. And that is something that a Resonance Driver doesn’t do. So, there is no loss of energy, and none of the energy from the vibrations is lost to the surroundings.