A Vibratory Hammer with a variable eccentric moment can be turned on and off without vibration.

- Safe working safe in urban areas, near railways

- Extensive range Excentric moment from 7,5 to 90 kgm

- Designed for the job Free hanging, leader guided or excavator mounted

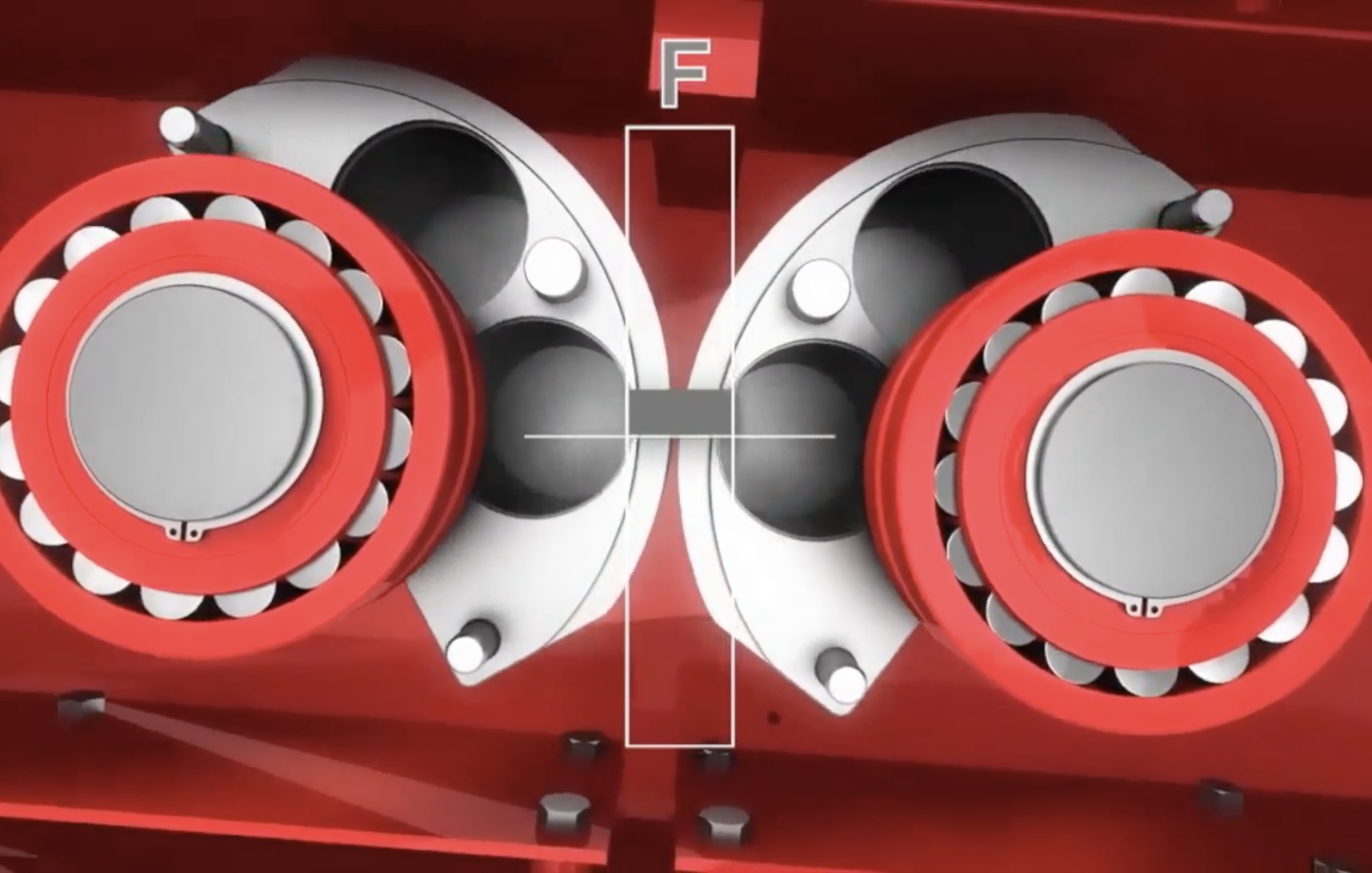

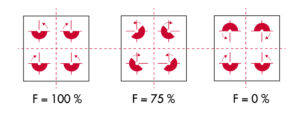

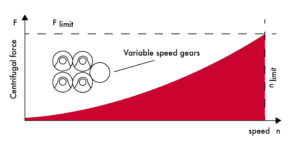

Variabel Moment means the eccentrics are adjustable into a zero moment position. Due to the opposite centres of gravity, the eccentric force will be cancelled. Only after the Vibratory Hammer has reached full speed, the eccentric moment is set, as a result of which the vibratory hammer will start to vibrate. It is possible to set the eccentric moment at a value from 0 to 100%. The operational rpm of these Vibratory Hammers is almost 50% higher than a Normal Frequency Vibratory Hammer. A High Frequency Variable Moment Vibratory Hammer will rotate with approximately 2.300 revolutions per minute.

0

years experience

in construction equipment

0

different types

per brand

0

places in the world

where we sell and service vibratory hammers

9 reasons to choose VM/RF

- Suitable in urban areas and vibration sensitive projects

- Adjustable eccentric moment

- Suspendable from telescopic mobile crane

- Forced lubrication system

- Gearbox cooling system

- Excellent quality

- Open loop hydraulic system

- Wide range of clamping solutions

- Advanced iQan operating system

A safe technology in the urban area

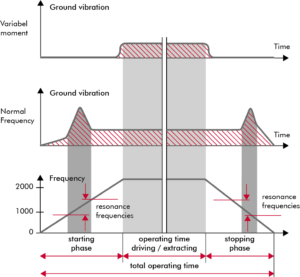

Due to the high rotational speed – as a result of which the Vibratory Hammer works further away from the soil’s resonance frequency – and due to the smaller amplitude, these Vibratory Hammers are less harmful to the surroundings. Also during vibrating or extracting a foundation element you can adjust the eccentric moment and therefore the amplitude. This results in an optimum adjustment of the Vibratory Hammer for the job and, as a safe technology for the surroundings.

A continuous Adjustable Moment also gives the operator the ability to control the installation of various profiles with great accuracy

A traditional Vibratory Hammer has a constant eccentric moment and an average rpm of 1.500 revolutions. Passing the critical frequency area during start-up and stop, will cause disturbing negative vibrations in the boom of the crane and in the soil; not just at the spot, but with a considerable perimeter distance.

Compared to a Normal Frequency Vibratory Hammer (1.500r pm), a High Frequency Hammer (2.300 rpm) produces less vibrations in the nearby surroundings: the vibro level of an HF Hammer measured at a distance of 2m from the driving element- equals the level of vibrations produced by a Normal Frequency Hammer at a distance of 16m!

When using a High Frequency Vibratory Hammer with Variable Moment (VM/RF) with an adjustable moment of 0 to max 2300 revolutions per minute, critical vibrations in start-up and stop are eliminated. After passing the critical frequency area, the eccenter weights are automatically adjusted and synchronised to the current eccentric moment.

Therefore, when driving in urban areas, it is best to use a Vibratory Hammer With Variable moment.

Applications

- Suitable in urban areas and vibration sensitive projects

- Safe working close to existing buildings, inner city, railways

- General pile driving projects

- Onshore & nearshore

- Suitable for most soil types

Vibratory Hammers

Excavator Mounted Vibratory Hammers

Upending Vibratory Hammers

Limited vibrations

Variable Moment (VM or RF) technology

A Vibratory Hammer with a variable eccentric moment can be turned on and off without vibration. For this, the eccentrics are placed in a zero position with an adjustment motor.

Working principle

The principle of a VM/RF Vibratory Hammer is based on adjustable eccentrics to achieve resonance free starting and stopping. During startup an adjustment motor shifts the eccentrics in to a zero moment position.

When the Vibratory Hammer reaches the desirable speed, eccentrics can infinitely be rotated and set to the eccentric moment. As a result the Vibratory Hammer will start to vibrate.

High Frequency

Due to a high rotational speed – as a result of which the Vibratory Hammer works further away from the soil’s resonance frequency – and due to the smaller amplitude, these vibratory hammers are less harmful to the surroundings. The ability to adjust both the moment and frequency makes a VM/RF Vibratory Hammer the perfect Hammer for different soil types and different profiles.

The variable eccentric moment of the Vibratory Hammer is m x r x sum of eccentric weights.

The adjustment of the eccentrics is completely automated. As manual (remote) control for shifting the eccenter weights is possible, the most ideal amplitude can be generated for each soil type.

It is not necessary to readjust the vibratory hammer when stopped and re-started. The hammer will automatically select the last setting. With VM/RF, it is possible to maintain the hammer at its maximum frequency while bringing the eccentric moment to 0. The Vibratory Hammer can be brought to standstill without causing any vibrations.

Vibrating with VM/RF works automatically and safe. It is an ideal equivalent of the pressing method.

Want our expertise? Connect with us!

Michiel Schaminée

Area Manager Benelux

Jos Hardeman

Senior Sales Area Manager - Mid-Europe, Scandinavia, UK