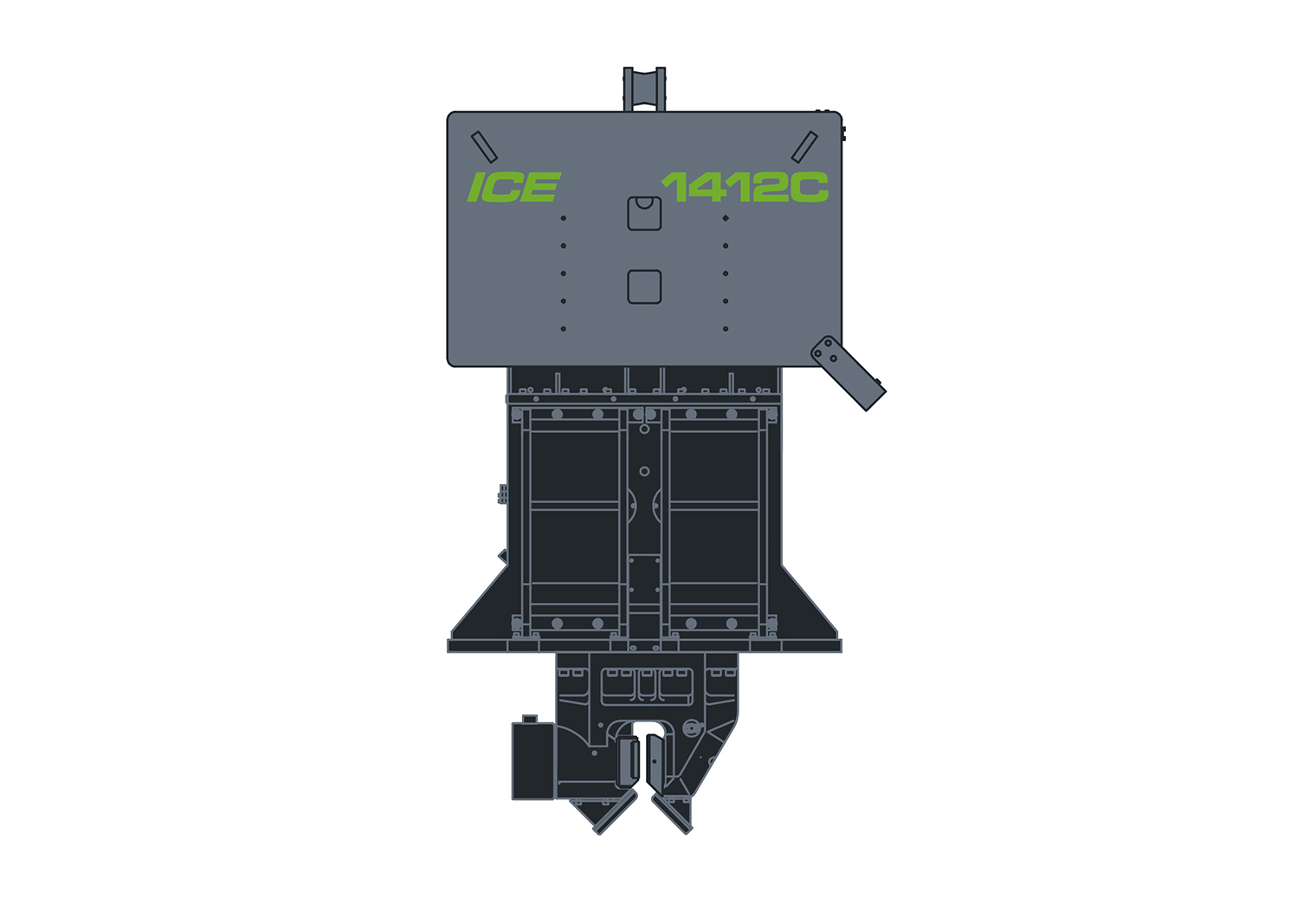

The Pile Lifting Device is fixed on the extraction head, and is connected to the positioning hole on the pile by a chain. The pile head is automatically lifted into the clamping plate of the fixture through the lifting of the oil cylinder, realizing the function of pile alignment. This process only takes about 1 minute.

Guangzhou Changda undertook the construction of the port in Mauritania. This is a newly built project on a desolate desert seaside, located on the border between Mauritania and Senegal. The project is located in a difficult environment, dozens of kilometers around is barren, and the necessities for life are supplied from the capital, which is more than 4 hours away by 200 kilometers away. Even the water used for washing is currently pulled back by vehicles from a distance of 40 kilometers. Because of this, construction efficiency is very important for Guangzhou to grow up.