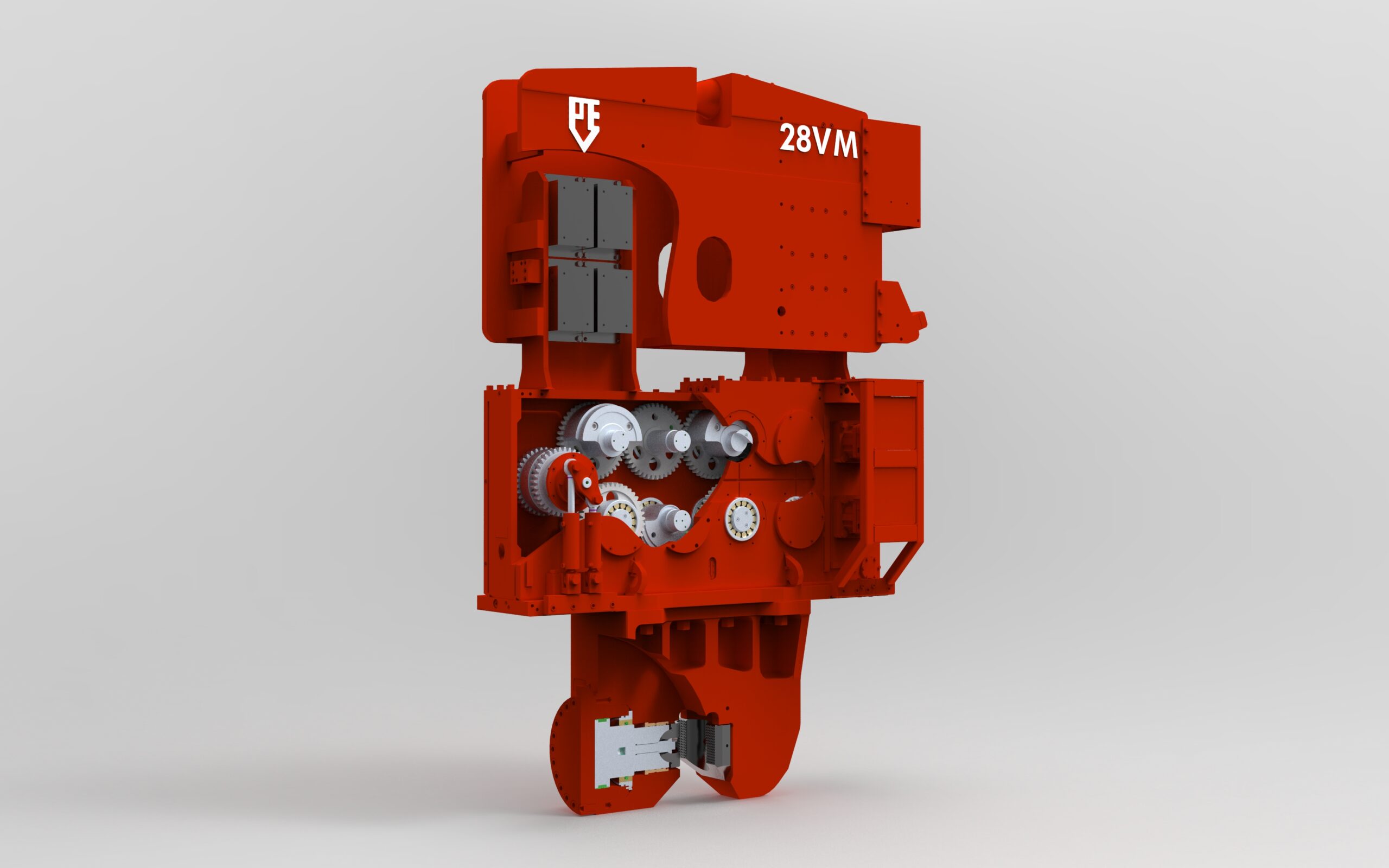

Giant modular vibratory hammer

If more power is needed or if larger tube diameters have to be installed, Dieseko gives the option of connecting vibratory hammers to a tandem application. The PVE 250M-series is modularly built and can be stacked in steps of 250 kgm to a combination of up to 2,000 kgm.