PVE recognizes the importance to adapt to changing circumstances during pile driving operations, especially when it comes to soil. For this reason the PVE hydraulic impact hammers are designed in a modular configuration. For every hammer type it is possible to adjust the impact energy by adjusting the drop height. This can also be accomplished by adding or removing drop weights.

- Sound proof Very sophisticated insulating system

- Accelerated Efficient pile driving operations and high production rates

- Designed for the job Measurestrike system

PVE impact hammers are excellent for lots of applications. The most common application is the installation of precast concrete piles. PVE impact hammers are also very suitable for driving steel casing piles, sheet piles and cast-in-situ concrete piles. The larger PVE impact hammers, starting from the PVE 10 NL, are very suitable for heavy piling works. Examples are driving large steel casing piles for bridge foundations, wind farm foundations or industrial projects for jetties, harbour quays and cable landing projects.

0

blows per minute

for the larger impact hammers

0

types

in our impact hammer range.

0

places in the world

where we sell and service impact hammers

7 reasons to choose an impact hammer

- High reliability and long life duration

- Cost efficient by fast and easy assembly on piling rig

- Fast and easy exchangeable drive caps and sleeves

- High efficiency by accelerated hammers with high blow rates

- Additional sound reduction systems available

- Professional monitoring and reporting by the Measure Strike System

- Adjustable drop weight due to the modular system of the impact hammers

Accelerated

PVE NL series impact hammers are accelerated to guarantee high performance. The accelerated PVE impact hammers ensure efficient pile driving operations and high production rates. The impact energy is adjustable for an optimal setting in relation to pile type, pile diameter and soil stiffness. The PVE NL series impact hammers are manufactured according high quality standards and with A-brand components. The PVE NL series impact hammers are well known for their long lifetime and high efficiency.

Soundproof

Especially in urban areas several challenges need to be taken into consideration when it comes to pile driving. PVE recognizes the importance of the continuity of pile driving while taking the surrounding area and neighbours into account. PVE offers a very sophisticated insulating system for the PVE NL impact hammer range. With the sound insulating system sound reductions up to 10 dB are possible compared to a standard impact hammer. PVE NL impact hammers are continuously subject to further developments for sound proofing and efficiency.

PVE offers several noise reduction accessories for all of the PVE hydraulic hammers.

Applications

- Installation of precast concrete piles

- Driving steel casing piles

- Driving sheet piles

- Driving cast-in-situ concrete piles

- large steel casing piles for bridge foundations, wind farm foundations or industrial projects for jetties, harbour quays and cable landing projects.

Wide modular range

PVE offers a wide range of hydraulic impact hammers which can be used in combination with every type of pile driving machine but can also be used free suspended in combination with a PVE power pack. Due to the stock and interchangeable components of the hammers, PVE has access to a huge spare parts inventory.

Because the required capacity of the hammers varies as a result of different pile types, sizes and soil conditions the possibility of adjusting the blow energy is a main advantage. Therefore the PVE hydraulic impact hammers are built in a modular configuration. The PVE impact hammer therefore is easily adjusted by adding drop weights in as required. For example a transformation of a PVE 4 NL impact hammer into a PVE 6 NL impact hammer is possible within only a few hours. The modular system is applicable on the complete range of PVE impact hammers.

MeasureStrike

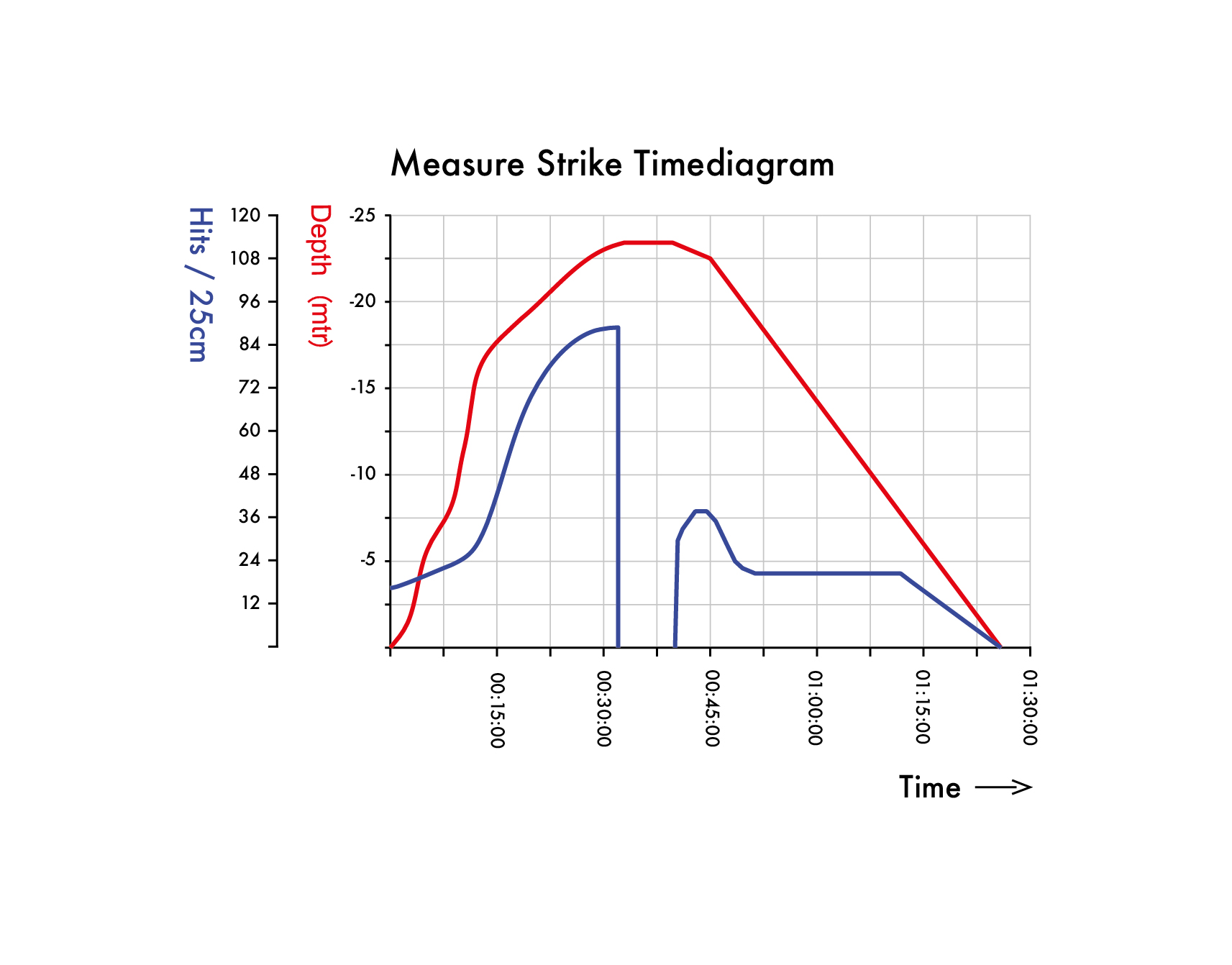

Quality and accuracy of your pile driving operation. For this reason we are offering the MeasureStrike system. The MeasureStrike system registers and reports for each pile number pile tip depths, the pile blow energy, pile driving time and blow count. The integrated WiFi application assists the operator in transferring data from the piling operations fast and easy to another device for information exchange. Piling data therefore is available anytime and can be shared within seconds.

Want our expertise? Connect with us!

Jos Hardeman

Senior Sales Area Manager - Mid-Europe, Scandinavia, UK

Christian de Heus

Sales Manager Woltman