An excavator can easily be turned into a sheet pile driver by connecting a Vibratory Hammer.

The excavator supplies the oil flow for the hammer and the force of the excavator boom is used to raise the penetration rate of the steel. Occasionally these joint forces means a smaller hammer can be used.

- Flexible Easy mounting and changing to the excavator(s)

- Extensive range Excentric moment from 3,2 to 23 kgm

- Designed for the job High frequency with or without RF/VM or Swivel Head

Maximum variety, minimum disturbance

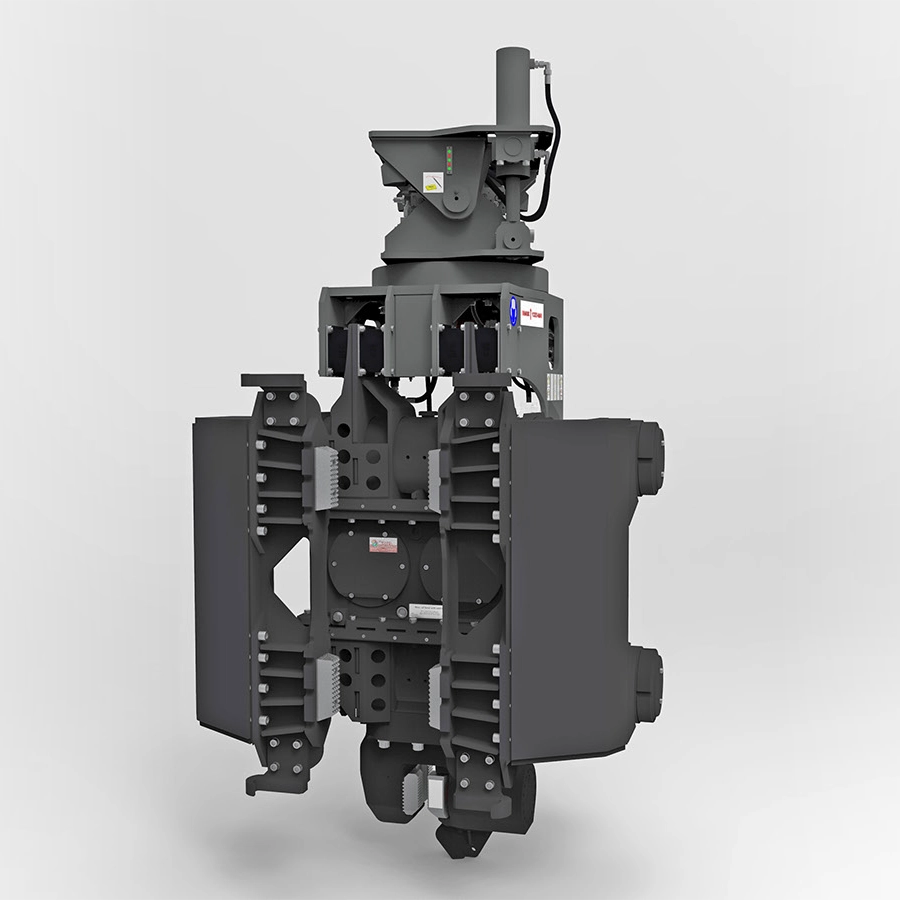

Our Excavator Mounted Vibratory Hammers are used to drive or extract various steel profiles; sheet piles, H-beams, and I-beams and the bigger types, fitted with double clamps, casings and tubular piles, can be driven. The Vibro Hammers have a very narrow throat width that allows you to carry out staggered sheet piling, and with a wide range of Vibratory Hammers and clamps, we have the solution for all types of steel, wood and concrete piles and all different soil conditions.

Swivel Head – Side Gripper

A swivel head is a real time-saver for pile-driving jobs. The manual interference is reduced by picking up a sheet pile in a horizontal position with a 90-degree tilting function. So almost nonstop piling operation is possible, and the operator can drive a sheet pile in less cycle time than the standard type pile driver. Our Side Gripper can rotate and tilt and, in the 90-degree tilted position, can also pick up a profile in a horizontal position.

The excavator-mounted series causes minimal ground vibrations due to its high rotational speed of approximately 2300 rpm. An additional range of Variable Moment / Resonance Free models allows you to drive steel piles with less disturbance on vibration-sensitive projects. Due to the excavator mounting, their extreme flexibility makes this kind of Vibratory Hammer our most agile equipment – especially in compact spaces.

0

years experience

0

diffrent types

0

places in the world

where we sell and service vibratory hammers

7 reasons to choose an excavator mounted vibratory hammer

- Easy to mount to almost all types of excavator

- High push/pull forces increase driving performance

- Goose neck for increasing working height and driving longer piles

- Swivel head series for single-operator use

- Improves the profitability of the excavator

- Easy maintenance

- Excellent quality

Excavator mounted series

Dieseko Group offers a range of five different models:

- ICE B & PVE A series: standard Excavator Mounted Vibratory Hammers

- ICE RFB & PVE VMA series: Resonance Free / Variable Moment Excavator Mounted Hammers

- ICE SH & PVE SH series: Vibratory Hammers with Swivel Head

- ICE RFSH & PVE VMSH series: Resonance Free / Variable Moment Vibratory Hammers with Swivel Head

- ICE SG & PVE SG: Side Gripper Vibratory Hammer

Applications

- Highly efficient for general driving and extracting

- Compact and light-weight for difficult access projects

- Low noise for urban area use

- Variable Moment / Resonance Free series for resonance free operating in

vibration sensitive locations

Vibratory Hammers

Resonance Free / Variable Moment

ICE 8SG Side Gripper

High production with the ICE 8RFB Vibratory Hammer driving sheet piles on the banks of a canal near Schagen in The Netherlands

Selecting the right excavator

To determine the correct excavator to use, as a guide, calculate that only 60 to 70 per cent of the installed power in the excavator will be available to drive the Vibratory Hammer. This percentage can be compared with the required hammer power.

When the maximum oil pressure and maximum oil flow are unknown or not available, please use the following table as a guide to match the Excavator Mounted Vibratory Hammer with the correct excavator.

Side Gripper

Dieseko Group builds hundreds of hydraulic Vibratory Hammers every year. Experienced and dedicated engineers are developing these hammers. Also users and clients are involved in the development process for finding the best solutions. Now these engineers developed a simple, rigid and extremely reliable Side Gripper. With this Excavator Mounted Vibratory Hammer you will work fast and efficient and with less staff. Even without a telescopic leader now you can drive the longest profiles with the newly designed side grip.

Our unique design:

Linear clamping movement

Results in less moving/wear parts as well as efficient clamping load transfer (cylinder force = clamping force). Less wear and tear parts, low maintenance costs, less downtime.

Multi directional elastomers

Elastomers are placed in multi directions giving better stability while operating the machine. This design also guarantees less stress on parts and construction.

Rigid centrifugal force load transfer

The centrifugal force load and clamp movement load is completely separated. Centrifugal forces are taken by the rigid structures (Gearbox, cylinder housings, clamping arms), while the clamping forces are taken by the cylinder rods.

Clamp claw exchange

Exchanging clamp claw configuration without changing the clamp arms for gripping sheet piles, casings up to ø 550 mm and H-beams up to H500.

With this Excavator Mounted Vibratory Hammer you will work fast and efficient

Want our expertise? Connect with us!

Jos Hardeman

Senior Sales Area Manager - Mid-Europe, Scandinavia, UK

Marion van den Akker

Area Manager BeNeLux